The problem?

As part of its industrial boiler production activities, one of our customers is currently involved in a dispute with its supplier following a labeling error on valves equipped with sleeves.

In order to remove any doubt about the conformity of the materials received, it wishes to confirm that the seals inside the valves are indeed made of FKM (fluoroelastomer)—a material known for its high chemical and thermal resistance—and not EPDM (ethylene propylene diene monomer), which is more suitable for aqueous or less aggressive environments, as indicated on the label.

In order to carry out this study, FILAB developed an analytical approach using Fourier Transform Infrared Spectroscopy (FTIR), a chemical analysis technique that can identify the molecular structure of many materials, particularly for the study of polymers.

Determine the physical and chemical composition of the valve sleeve seal.

Objective:

This step aims to confirm that the valve and its seal have the necessary characteristics to transport the fluid passing through the valve, namely a synthetic gas produced by the carbonization of wood, a complex mixture containing corrosive and volatile compounds.

Another purpose of this study is to verify that the seal has not deteriorated during use.

Approach:

For this study, the technique used is Fourier Transform Infrared Spectroscopy (FTIR) between 4000 and 400 cm-1. This technique involves subjecting the sample to infrared radiation: each type of chemical bond absorbs a specific wavelength, which provides a true "chemical fingerprint" of the material.

With this analytical technique, the material is identified in two stages.

The characteristic peaks are extracted to search for the corresponding bonds in reference tables. The continuous spectrum is then compared to a spectral database, which allows the nature of the material to be determined accurately through maximum correspondence calculations.

At the same time, FTIR analysis allowed us to check for any abnormal degradation of the seal by comparing used samples.

Comparative study of the two joints - compliance study

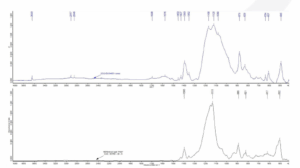

Spectroscopic analysis of the sample reveals several characteristic absorption bands, including C-F and C-C bond stretching (between 1393 and 1080 cm⁻¹), CF and CH vibrations (between 829 and 720 cm⁻¹), and CF₂ group deformations groups (around 634 and 607 cm⁻¹).

These signals are characteristic of a fluorinated elastomer. The results as a whole therefore lead to the conclusion that the seal analyzed is made of a material of the FKM (fluoroelastomer) type, commonly used for its chemical and thermal resistance properties.

Comparison of the FTIR spectrum of the customer sample (blue) and a "FKM" reference (black).

In addition, to assess any abnormal degradation, a comparison was made between samples of seals in service and new samples. The results show that the used seal retains the same chemical characteristics as the new seal: no alteration or degradation of the material was detected.

Conclusion of the comparative study

Thanks to the analysis carried out using Fourier Transform Infrared Spectroscopy (FTIR), our teams were able to confirm the exact nature of the polymer used in the seals: it was indeed FKM (fluoroelastomer) and not EPDM, as suggested by the supplier's labeling.

This precise identification made it possible to remove any doubt about the conformity of the parts and rule out the possibility of a material error.

Furthermore, a comparison between new and used seals showed no significant chemical degradation: the material retained all its properties over time.

Our customer was able to continue production without concern, with no impact on the safety or performance of its facilities.

This study perfectly illustrates how material characterization goes beyond simple testing to ensure industrial safety and maintain trust between partners.