Ajoutez votre titre ici

The problem

A company specializing in the manufacture of heat exchangers for industrial installations wishes to expand its market to coastal areas.

Its standard product, made of 304L stainless steel, performs well in conventional environments (fresh water), but the company is hesitant to use a more expensive copper alloy for applications in saline environments. It needs quantitative data to justify this technical and commercial choice to its customers.

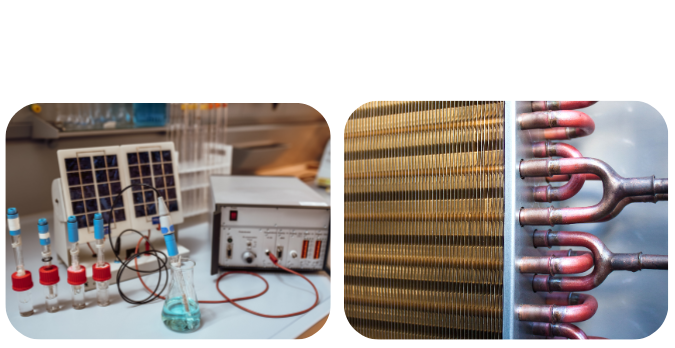

To address this issue, FILAB has developed an approach based on electrochemical analysis.

Identify the most suitable material for use in saline environments

Objective:

The objective of this study is to assist our client, who specializes in manufacturing heat exchangers for industrial installations, in selecting the most suitable material for use in saline environments. Should they continue to use 304L stainless steel or switch to a corrosion but more expensive?

This analysis is essential because it aims to provide the knowledge needed to avoid problems when using these products.

Our technical approach

To objectively compare the two materials, we set up a simple and effective test plan based on the technique of electrochemical analysis:

• Standardized test specimens (metal coupons) made of 304L steel and copper alloy were immersed in two different environments: a simulated fresh water solution and an artificial seawater solution.

• We first measured the open circuit voltage (OCV) to observe the spontaneous behavior of each metal in each environment. This measurement is a fundamental piece of data in surface electrochemistry.

• Next, using linear sweep voltammetry (LSV), we accelerated the process very slightly to accurately determine the corrosion rate. LSV is a common technique in electrochemistry for quantifying reaction kinetics, in this case the rate of metal dissolution (corrosion).

The benefits of this analysis for the clien

The figures in μm/year confirm that the choice of material must be strategically adapted to the operating environment.

• Justification for the additional cost: The initial additional cost of the copper alloy is fully justified in marine environments by the extended service life of the heat exchangers and their increased reliability. This choice minimizes long-term maintenance and replacement costs, offering better overall value for coastal customers.

• Commercial positioning: this study gives the company a competitive advantage by enabling it to defend a rigorous technical argument. It can now target coastal markets with a scientifically validated solution, reinforcing its image as an expert in the field of material selection and the control of electrochemical corrosion risks.

Conclusion of the stud

This comparative electrochemical study quantified the difference in behavior between 304L stainless steel and copper alloy in different environments, providing a solid technical basis for decision-making.

In conclusion, for market expansion into coastal areas, copper alloy is the optimal technical solution and the most economically viable in the long term, guaranteeing the performance and reliability of equipment.