Training in surface analysis

objectives

In-depth understanding of the mechanisms governing surface properties

Ability to interpret the results of analyses to guide decision-making on product development or process improvementsn de processus

Ability to select and apply appropriate surface analysis techniques according to the specific needs of a project or research project

Pedagogical resources

- Screening of training material

- Handover of training material

- Training led by experts in the techniques required

Target audience

Technicians or engineers in charge of research & innovation, process & industrialisation, production & maintenance, quality control, health, safety & environment, purchasing & supplies …

Program

For more information on the program, please contact us

Information updated on 07.10.2024

Practical information

- In-company training

- Questionnaire at the beginning and end of the course (Quizzes)

- Attendance sheet

- Duration: 2 days

- PRM and PSH accessibility

- Adaptable to customer needs

- Price on quotation

- No pre-requisites required for this course

- A certificate of completion will be issued at the end of the course.

Our training courses are accessible to people with disabilities. We will offer you solutions for adaptations (e.g. training aids, pace of training, teaching support, etc.) and adjustments to suit your needs.

Your teams need training in suface analysis

What is the principle of surface analysis techniques?

The term surface analysis refers to the surface of a material. This is a vulnerable area where many interactions exist with its environment. This zone is endowed with several so-called specific characteristics, so that the material responds to the performances afterwards.

The knowledge of the properties and surface states of a material can allow you to adapt your manufacturing processes. Thus, it is possible to implement surface treatment or cleaning processes.

Why train in surface analysis?

Understanding the properties and conditions of a material’s surface is crucial. It enables you to adjust your production methods accordingly, by incorporating specific surface treatment or cleaning techniques.

The applications of surface analysis are many… you will be able to..:

solutions

Analyze the chemical composition of the surface of a material

Characterize the surface coating

Analyze and characterize surface treatments

Characterize the surface treatment baths

Study the morphology of the surface of a material (porosity, roughness,...)

Study failures and surface defects (cracking, rupture, migration, corrosion...)

Développer les traitements de surface

Identify surface pollution (analysis of particles, deposits, etc.)

FILAB's surface analysis training...

When should a surface analysis be carried out?

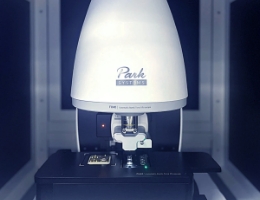

You wish to answer your problems of surface analysis? You have just acquired different technical means to perform a surface analysis (SEM-FEG EDX, Optical Microscope, BET, µ-IRTF) in your laboratory? The competent person(s) are no longer part of your team? You wish to improve your expertise on surface analysis and the exploitation of the results?

Why choose FILAB for your surface analysis training courses?

As an accredited training organization, FILAB supports your teams in the use of surface analysis techniques, regardless of your sector of activity.

At FILAB, we develop and offer our customers tailor-made training courses that are in line with your industrial issues or analytical challenges.

Technical resources used in surface analysis training

To register for the course or to obtain a quote, please contact us directly by email or telephone.

Training will start within 3 months of acceptance of the agreement.