The problem?

Faced with an issue related to the varying behaviour of its liquid product depending on different supplier formulations, one of our pharmaceutical clients wanted to measure the contact angle and surface tension of its samples deposited on three different substrates.

The client called on FILAB to verify that the formulation, in this case eye drops, exhibited optimal wetting behaviour on several types of surfaces.

Understanding the wetting behaviour of a drop on a substrate

Objective:

The aim of the study is to measure the contact angle and surface tension of several formulations on three different substrates.

- silicone support,

- neutral polyethylene support,

- polyethylene support with antimicrobial agent.

The approach used

Approach :

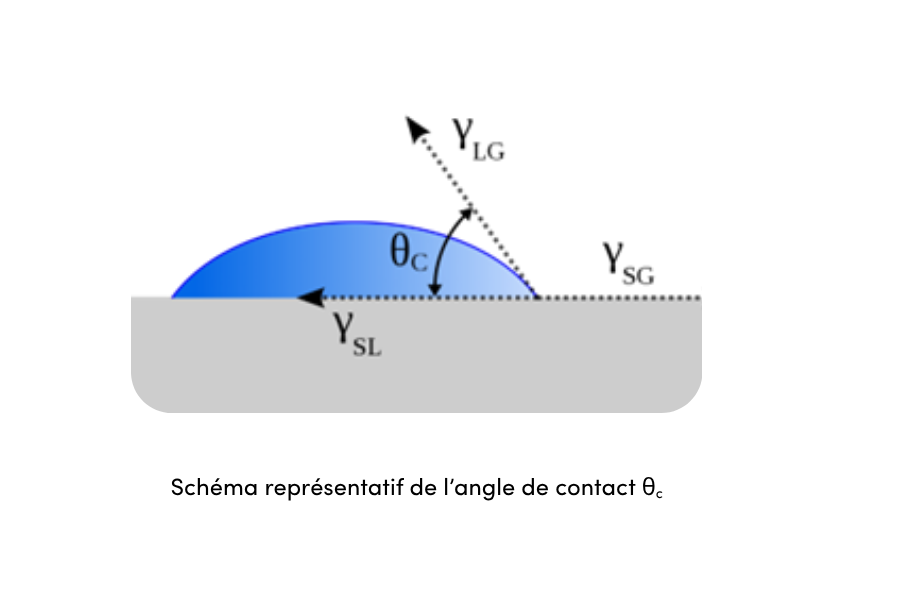

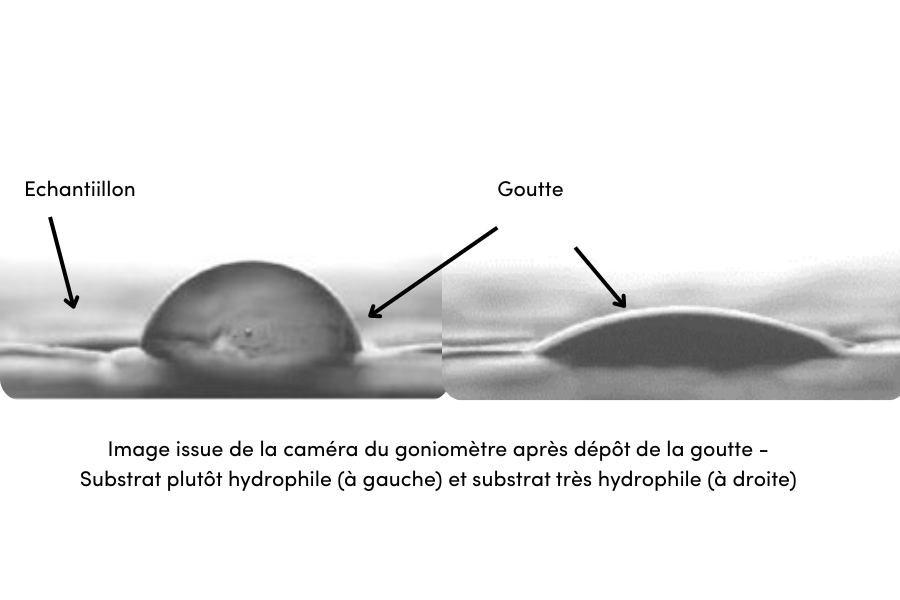

The technique used is goniometry, specifically the sessile drop method. A 4 µL drop of water (the model liquid) is placed on each sample. Measurements are taken a few seconds after placement, once the drop has reached a stable state. Each formulation is tested on the appropriate substrates.

For each formulation, surface tensions and contact angles are measured and compared between the different substrates.

Conclusion of the study

According to the analysis report, the nature of the substrate significantly influences the behaviour of the formulations. For the same formulation, the spreading and adhesion properties vary significantly depending on the contact surface.

Conclusion :

This study revealed that surface tensions are generally higher on polyethylene substrates than on silicone substrates.

Observation of the droplets shows that the silicone substrate is more hydrophobic than the polyethylene substrate, since the droplet forms a larger contact angle and lower surface tension on this substrate. This simple observation perfectly illustrates the interaction between this formulation and the tested surfaces.