How does FILAB help its customers to recover value from their industrial waste?

In an ever-changing industrial landscape, many manufacturers encounter material residues in the production of their products. These residues can vary in quantity depending on the manufacturing process.

This case study focuses on how the FILAB laboratory helped three separate clients to recover value from their industrial residues, transforming environmental and economic challenges into sustainable opportunities.

Manufacturers face two major problems: the use of expensive raw materials and the costly management of industrial waste. The generation of industrial waste represents a significant cost, particularly in terms of disposal and classification. These challenges hinder both operational performance and environmental performance improvements for companies.

Understanding the issues...

Today, industrial waste recovery presents a twofold challenge:

- It generates new resources as raw materials for certain industries

- It reduces the impact on the environment and health.

Three of FILAB's industrial clients recently approached the laboratory with the following requests:

- Client 1: recovery of waste consisting mainly of quartz and lime

- Client 2: recycling steel industry waste (dust and slag)

- Client 3: recycling solid and liquid waste from battery shredding and washing water

Launch of analysis at the FILAB Laboratory: Our solutions, our routine!

Pre-analysis approach:

First, to support the three manufacturers, FILAB studied the elements of interest. These elements may be found in waste depending on the raw materials and processes used. The idea here was to detect and determine the elements that might be of interest to them for subsequent recovery.

After this initial step, each of the manufacturers wanted to continue the study in different ways:

- Client 1: After discussions with this first manufacturer, they wanted a very broad study of the metal and mineral fractions found in their product.

- Client 2: They wanted to determine the precise content of metals (aluminum, iron, copper, cobalt, nickel, etc.) and rare earth elements (cerium, lanthanum, yttrium, etc.).

- Client 3: He wanted to know the metal, precious metal (platinum, palladium, gold, etc.), and halogen (such as fluorine) content.

Analysis of minerals, metals (including precious metals), and rare earth elements at FILAB

The first step is to prepare the sample. This allows a clear liquid solution to be obtained from a solid sample, in which all the elements of interest are dissolved. This step is known as "mineralization" or "acid digestion."

FILAB treats each sample individually, optimizing the choice of acids and mineralization conditions.

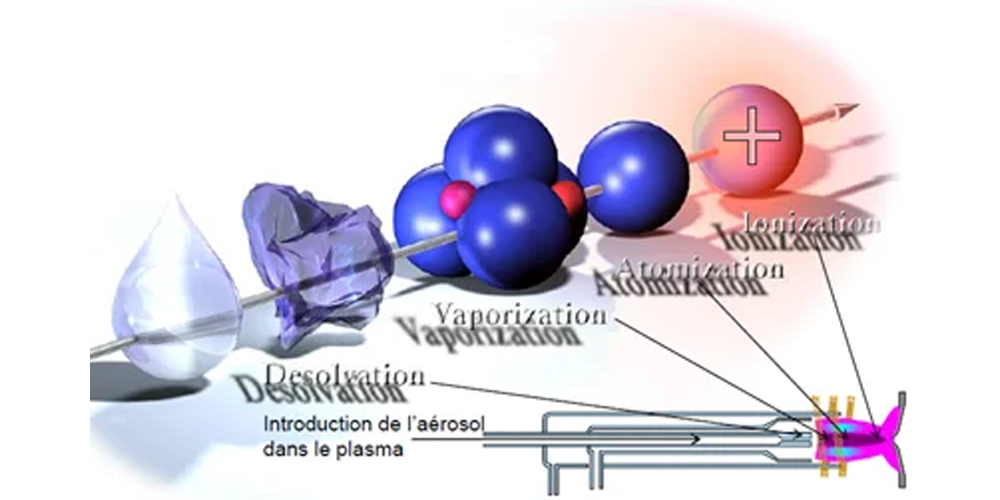

Once the mineralization solution has been obtained, FILAB uses the ICP (Inductively Coupled Plasma) technique, which breaks down the sample as it passes through a plasma.

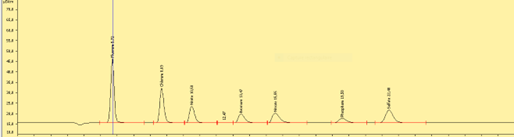

This technique is coupled with either an atomic emission spectrometer (ICP-AES) to determine major elements or concentrations greater than 1 mg/kg (0.0001%) or a mass spectrometer (ICP-MS) to analyze traces (less than 1 mg/kg).

These cutting-edge technologies in our laboratories enable the analysis of more than fifty different elements.

FILAB halogen analysis

When searching for halogens such as fluorine or bromine, for example, the preparation principle is also to obtain a liquid solution, but several methods of solution preparation are possible (combustion under oxygen, for example).

This solution is then injected and quantified using one of our four ion chromatography (IC) systems.

The results obtained

FILAB's in-depth analysis made it possible to accurately determine the concentrations of various elements in each client's waste. This information was essential in guiding clients toward the recovery methods best suited to their specific needs.

FILAB's approach enabled the efficient recovery of industrial waste, providing new sources of raw materials and reducing environmental impact. These cases demonstrate FILAB's expertise in solving complex problems and its commitment to sustainable industrial solutions.