The problem?

A Cosmetics manufacturer is updating one of its product lines, specifically its packaging, which it now wants to be made from the bio-based biopolymer PLA – Polylactic Acid. This innovative material addresses the company's commitment to eco-design and reducing its plastic footprint, while maintaining the high-end look demanded by the cosmetics market.

During the laser marking process, the client observed inconsistent ink adhesion, localized discoloration of the material, and even deformation under the laser marking process.

These anomalies raised questions about the biopolymer's compatibility with existing industrial processes.

To address this issue, FILAB sought to understand the biopolymer's behavior in the face of the marking process in order to identify the causes of the observed defects and guide the selection of technical solutions (formulation adjustments, marking parameter settings, or surface treatment).

Summary

Understanding the reasons for the marking defect through a multi-faceted analytical approach

To help the client characterize their biopolymer and identify the factors causing defects, FILAB implemented a multi-technical approach combining chemical, thermal, and surface analysis:

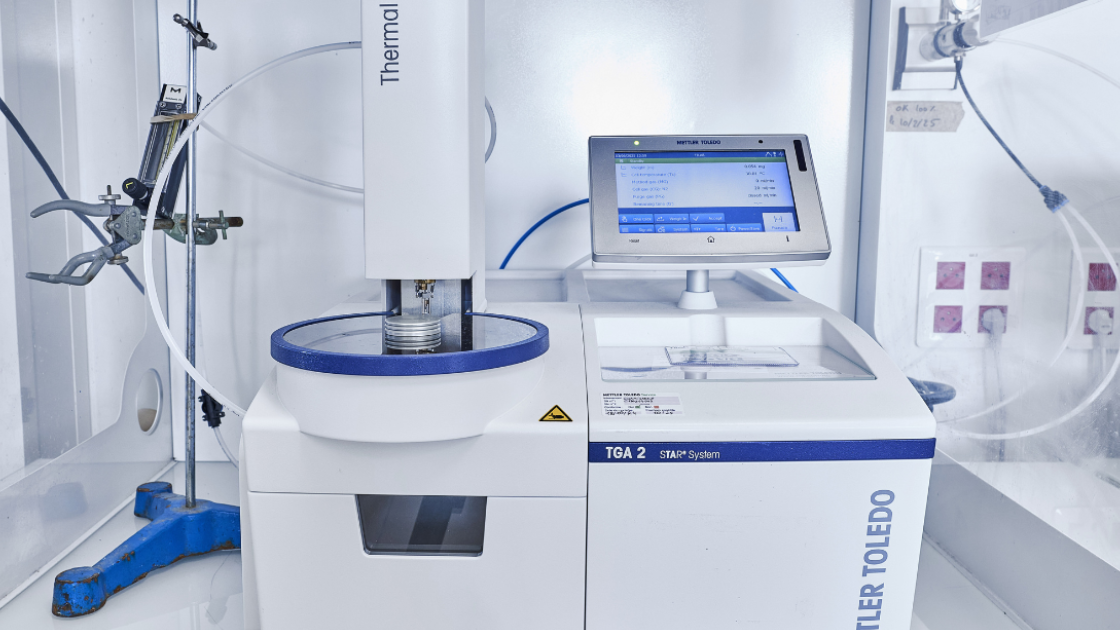

First, we analyzed the chemical composition of the material using TGA and FTIR to identify the polymer type, additives, and plasticizers.

Second, we examined the surfaces (before and after marking) using optical microscopy and SEM to detect any microcracks, deposits, or thermal deformations.

The third step involved studying the topography and roughness of the biopolymer to determine its 3D profilometry, measuring contact angles to assess surface energy, and evaluating ink compatibility.

Finally, we analyzed the thermal effects of laser marking using TGA and DSC to identify areas of oxidation or carbonization of the polymer.

Finally, we compared the behavior of this new bio-based biopolymer with a previously used PET control material. This approach aims to quantify the differences in behavior and guide future technical considerations.

Results and interpretation of the study of the bio-based PLA biopolymer

Analysis conducted by the FILAB laboratory teams on the PLA-based biopolymer used by our client for packaging its cosmetic products have revealed the following:

- The biopolymer's thermal sensitivity explains the alterations observed under laser marking.

- A low surface energy makes ink adhesion difficult without pretreatment.

- The possibility of chemical contamination or premature degradation of the material has been ruled out.

These results have led to a detailed understanding of the failure mechanism of the laser marking on our client's new packaging.

The solutions proposed by FILAB to resolve this marking defect

Based on the analytical results obtained, the FILAB laboratory was able to support its client by proposing several concrete optimization strategies to resolve their marking problem on PLA packaging.

To address adhesion issues, one approach involves applying a surface treatment (such as corona, plasma, or flame treatment) to improve the material's wettability. Simultaneously, a technical review of the laser parameters, including its power, frequency, and pulse duration, would refine the marking accuracy.

Regarding the material itself, FILAB recommends adapting the biopolymer formulation to enhance its thermal resistance to the stresses of the marking process. Finally, the laboratory guided the client toward selecting an ink or marking method specifically compatible with the identified chemical composition of the packaging, thus ensuring optimal and long-lasting adhesion.

The benefits of this study for the client

Thanks to FILAB's support on this biopolymer packaging marking challenge, our client now benefits from a thorough understanding of the complex interactions between their material and the marking process. This scientific expertise has enabled our client to improve production through optimal calibration of the marking machines and, consequently, to optimize the development time for their new packaging range. Ultimately, this approach guarantees a significant improvement in quality, both aesthetically and functionally, thus ensuring the reliability and appeal of the finished products on the market.

Conclusion of the study

In conclusion, thanks to its expertise in polymer and biopolymer characterization, the FILAB laboratory enabled its client to precisely identify the source of the marking problem and define concrete corrective measures to adapt its industrial process to this new bio-based material.

This approach, which combines the analytical rigor of the FILAB laboratory with genuine technical support, directly contributes to sustainable innovation, a strategic imperative for the cosmetics industry.