La problématique ?

In an effort to improve the sustainability of its polymer parts, an industrial player called on the FILAB laboratory to evaluate the thermal behavior of two PVCs intended for the manufacture of 3D-printed parts.

The client requested FILAB's assistance with this quality initiative.

To address this issue and determine the activation energy, the FILAB laboratory used ATG as a simulation and analysis tool to anticipate the aging of PVC-printed parts.

Context of the analysis

Approach :

The objective of this study is to determine the activation energy, i.e., the energy required to initiate the decomposition of two polymer materials of different chemical nature (black sample and white sample).

The standard used to conduct this study is ASTM E1641. This standard describes a standardized method for determining the activation energy (Ea) of a thermal decomposition process based on data obtained by thermogravimetric analysis (TGA).

Principle of the method :

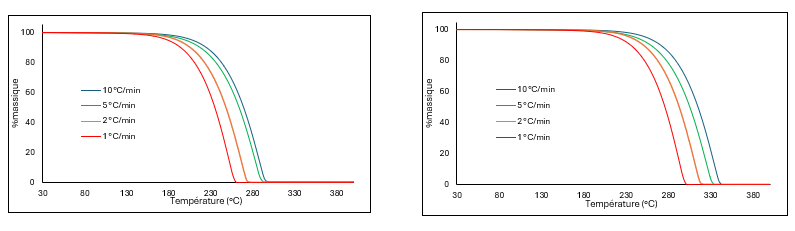

Several ATG analysis are performed on the same sample at different heating rates (here: 1, 2, 5, 10 °C/min). For a given conversion rate (10%), the characteristic degradation temperatures are recorded for each ramp.

Methodology and technique used

Thermogravimetric Analysis (TGA) :

Thermogravimetric analysis (TGA) is a technique used to monitor the mass change of a sample subjected to a gradual increase in temperature in a controlled atmosphere.

As part of the study, it was used to observe the thermal degradation behavior of the polymers tested, identify critical mass loss temperatures, and model the degradation kinetics in order to extract an activation energy (Ea) associated with the phenomenon.

This method is applied to both samples in order to compare them. For each sample, four curves are obtained with different temperature ramps.

Conclusion of the comparative study

The four analysis carried out with different ramps on the two PVC samples intended for 3D printing show that, for the same conversion rate of 10%, the two materials analyzed have significantly different activation energies :

The black sample has a rate of 139.91 kJ/mol, while the white sample has a rate of 206.76 kJ/mol.

This difference indicates that the white polymer requires more energy to initiate thermal degradation than the black material. In other words, it is more thermally stable and therefore more suitable for 3D printing.

Black sample White sample