Unknown particles in your pharmaceutical products

The problem?

Identification of unknown particles: from emergency response...

On Friday at 8:05 a.m., the quality manager of one of our long-standing customers contacted us: a few days earlier, her team had identified the formation of particles, random materials, on an entire batch of products, blocking production while the investigation was underway. Internal investigations had failed to identify the source of this contamination, and no significant changes in the process had provided any clues to guide the investigation.

Analysis and findings

Upon receiving the samples, we were able to filter and then isolate the particles from the solution. These particles were then subjected to a general diagnosis using the technological resources available in the laboratory.

Here is a detailed overview of the findings from the various analysis techniques used:

Scanning Electron Microscope

The SEM, coupled with an EDX probe, allowed us to see the chemical homogeneity and morphology of the particles. This enabled us to make an initial diagnosis of their composition. In this case, the particles were organic residue.

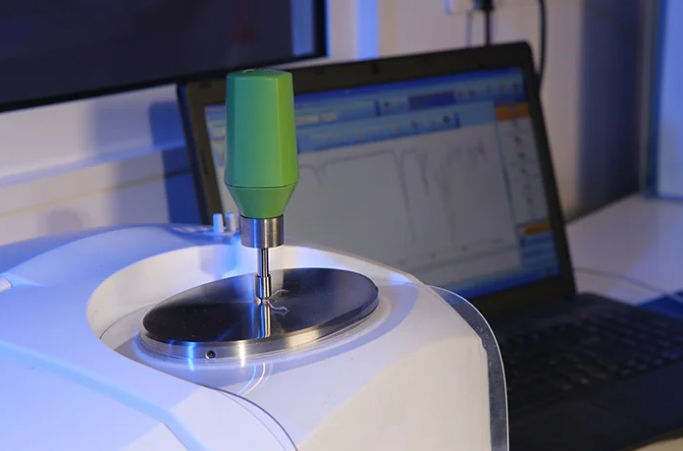

Spectroscopy and Fourier transform infrared microscopy (FTIR and µ-FTIR):

FTIR was used to identify the nature of the chemical bonds that make up the particles.

Mass spectrometry (GC-MS):

GC-MS chromatographic analytical techniques were used to perform a qualitative assessment of the molecules present.

Thanks to all of these complementary techniques and their urgent implementation, our client was able to obtain a concrete diagnosis in less than 24 hours. The substance was cellulose.

Summary of results

This information is certainly essential, but it was not sufficient for our client to conclude on the origin of this pollution and implement immediate actions to resolve the problem.

The combination of different analysis techniques provided a detailed understanding of the degradation mechanisms.

A comparative analysis of cellulose fibers and the sampled material concluded that these particles came from paper rags used in the manufacturing process.

To remedy this, our teams worked with the client to implement continuous improvements to the production process, including the use of more suitable sampling methods that did not risk particle emissions.

Recommendations

Tailored support for concrete and lasting results

To ensure product quality in the event of non-compliance, the FILAB laboratory recommends:

- Particulate cleanliness, which is a requirement throughout the production cycle of a pharmaceutical product.

- Implementation of regular checks and process optimization to reduce the risk of contamination.

Conclusion of the study

The discovery of the source of contamination by unknown particles and the implementation of continuous improvements in the production process have transformed a critical challenge into an opportunity to optimize and enhance product quality.

By identifying the origin of the particles as paper towel residue, FILAB guided the client toward concrete changes in its production methods, thereby ensuring a reduction in the risk of future contamination.

Ultimately, our goal at FILAB is not only to solve our clients' immediate problems but to support them in achieving sustainable operational excellence. Through our expertise and tailor-made support, we are committed to being a trusted partner for concrete and lasting results, thereby enhancing the quality, safety, and performance of the industry.