Material Laboratory

As an industrial professional, you may be looking for a materials laboratory capable of conducting precise analyses

The Filab laboratory is a leading expert in the physico-chemical analysis of materials. With a multidisciplinary team and proven expertise, our laboratory offers tailored services for various materials across all industries.

Materials analyzed at FILAB

At FILAB, we analyze a wide range of materials, each with unique characteristics and varied applications across different industrial sectors. With advanced expertise and cutting-edge equipment, FILAB can conduct in-depth analyses of various materials, providing tailored solutions for industrial needs in material characterization.

Metals are important in industries like automotive, aerospace, and construction. At FILAB, we analyze metals to determine their chemical composition, mechanical properties, and corrosion resistance.

- Premature Corrosion: Metals can corrode quickly, causing structural failures in maritime or petrochemical industries.

- Material Fatigue: In aerospace and automotive industries, metals may develop cracks and unexpected breaks due to repeated load cycles.

- Metal Contaminations: In industrial production, impurities can affect the final product's quality, requiring quick identification and elimination.

Polymers are used in various applications, from plastics to elastomers. FILAB offers comprehensive polymers analysis to evaluate their structure, physical properties, and behavior in different environments.

- Accelerated Aging: In outdoor or chemically exposed applications, polymers can degrade rapidly, affecting functionality.

- Adhesion Issues: Polymers may have difficulty bonding with other materials, which is critical in packaging or electronics industries.

- Stress Deformation: Under prolonged load conditions, polymers can deform, compromising product performance.

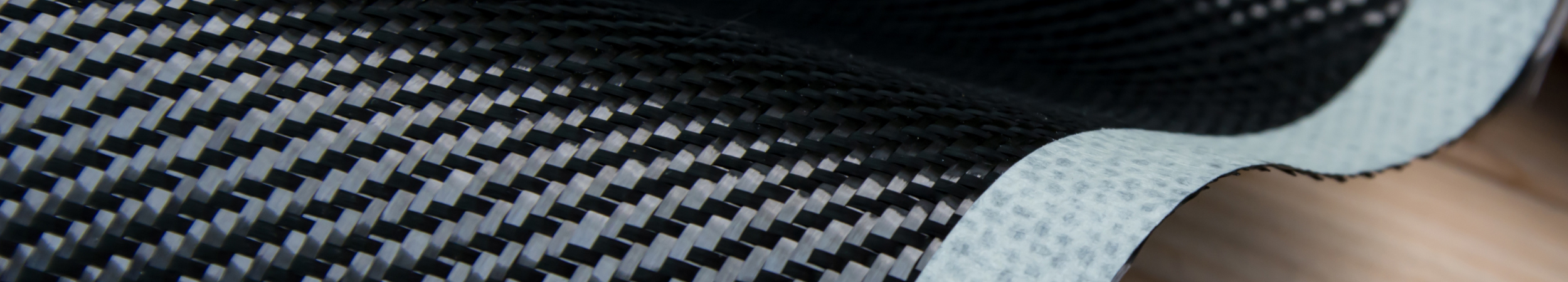

Composites, made of several materials, are increasingly used in sectors requiring lightweight and robust materials. At FILAB, we analyze composites to understand phase interactions and optimize their performance.

- Delamination: In aerospace or sports industries, composite layers can separate under stress, reducing overall strength.

- Material Fatigue: Composites can deteriorate under repeated load cycles, especially in structural parts.

- Quality Variability: Composite manufacturing can lead to uneven distribution of fibers or resins, compromising part performance.

Ceramics are non-metallic, inorganic materials used for high-temperature resistance and hardness. FILAB provides in-depth ceramics analysis to ensure their performance in extreme environments.

- Fragility: Ceramics can be sensitive to mechanical shocks, causing sudden and unexpected breaks, challenging in mechanical or electrical applications.

- Wear Resistance: In abrasive environments, ceramics can wear down quickly, reducing component lifespan.

- Thermal Sensitivity: Rapid temperature changes can cause cracks in ceramics, posing problems in industries where temperatures fluctuate.

Glass, used in applications ranging from optics to construction, requires precise characterization to ensure quality. FILAB offers analysis services to evaluate the composition and physical properties of glass.

- Spontaneous Fracture: Glass can break unpredictably under thermal or mechanical stress, which is a major issue in construction or electronics industries.

- Chemical Degradation: Under certain conditions, such as exposure to aggressive chemical agents, glass can lose its properties, compromising product functionality.

- Impurities: Defects or impurities in glass can affect its strength or appearance, creating quality issues in high-precision products.

Powders, whether metallic or polymeric, are increasingly used in manufacturing processes such as additive manufacturing (3D printing). FILAB offers detailed analyses to characterize particle size, composition, and reactivity of powders.

- Agglomeration: Powder particles can clump together, affecting flowability and precision in additive manufacturing or molding processes.

- Reactivity: Some powders may react with air or moisture, compromising their stability and performance during processing.

- Particle Size Variability: Irregular particle size distribution can lead to defects in finished products, a recurring issue in 3D printing or powder metallurgy.

Why consult a materials laboratory?

Consulting a materials laboratory is important for industries aiming to ensure the quality, performance, and durability of their products. Materials such as metals, polymers, composites, and ceramics significantly impact the success of manufacturing and the use of industrial components.

In many sectors, the materials used must comply with strict standards and regulations (e.g. ASTM, ISO). A materials laboratory can verify the conformity of raw materials and finished products, thus avoiding non-conformities that could lead to sanctions or product recalls.

For example, in the automotive sector, it is possible to ensure that metal alloys used in the manufacture of engine parts comply with European standards (EN) for corrosion and fatigue resistance.

Materials laboratories can help optimize manufacturing processes by identifying the most suitable materials or suggesting improvements to existing processes. This can result in better product performance and lower production costs.

When a product shows signs of failure, whether cracking, corrosion or premature wear, a materials laboratory can diagnose the causes of these problems. This enables solutions to be found to prevent the recurrence of these failures.

Materials laboratories also play a role in innovation, enabling the development of new materials or the improvement of existing ones. This enables companies to remain competitive and respond to changing market needs.

In the medical industry, a company may be looking to develop a new type of prosthesis that is stronger and more biocompatible. The FILAB laboratory is able to test different polymers and composites to identify the best solution. This work enables an innovative product to be launched on the market, offering improved performance and greater durability.

Materials can present significant safety risks, such as chemical reactivity, toxicity or degradation under certain conditions. A materials laboratory can assess these risks and propose solutions to mitigate them.

For example, a medical device manufacturer can ensure that the materials used in its products comply with biocompatibility regulations. After laboratory testing, it turns out that certain components are unexpectedly toxic. Thanks to the analysis, the manufacturer can adjust the formulation to guarantee user safety and regulatory compliance.

The FILAB laboratory analyzes your materials, both raw materials and finished products

Whether to ensure compliance with standards, optimize production processes, solve failure problems, innovate or guarantee product safety, the FILAB laboratory offers materials-related expertise. Through rigorous analysis and testing, we help companies to control material properties, reduce risks and improve product quality.

Our services based on material types

Our laboratory offers specific services for metals and alloys, from analysis of chemical composition to assessment of mechanical properties and corrosion resistance. We are particularly involved in the appraisal of metallic materials used in the aerospace, automotive and defense industries.

- Chemical characterization (ICP, OES).

- Microstructural characterization: grains, phases and defects via SEM.

- Mechanical testing: tensile strength, hardness, fatigue.

- Corrosion and oxidation analysis.

Polymers, whether thermoplastics, thermosets or elastomers, are also among the materials that FILAB engineers master perfectly. Our expertise enables us to analyze the chemical structure, mechanical properties and durability of polymers in a wide range of environments.

- Identification of polymers and additives (FTIR, NMR).

- Ageing and degradation studies.

- Mechanical analysis (traction, flexion, impact).

- Thermal analysis: DSC, TGA to study thermal stability and degradation.

- Expertise in adhesion and bonding issues.

Ceramic and glass materials present characterization challenges due to their complex nature. Filab has the resources needed to study the microstructure, chemical composition and thermomechanical properties of these materials.

- Chemical analysis: Determination of oxides and impurities, and elemental composition.

- Thermal characterization (ATG, DSC), softening point, thermal expansion.

- Study of crystalline phases by X-ray diffraction.

- Porosity and density analysis.

- Assessment of mechanical properties (hardness, breaking strength).

Composite materials, increasingly used in high-tech industries, require a specific analytical approach to assess the interactions between the different phases of the material. Our laboratory offers comprehensive solutions for composites analysis.

- Characterization of fibers and matrices by chemical and mechanical analysis.

- Study of interfaces and material adhesion.

- Mechanical performance testing.

- Expertise in delamination and fatigue issues.

Powders, whether metallic, ceramic or polymeric, are increasingly used in manufacturing processes such as additive manufacturing (3D printing). FILAB offers detailed analyses to characterize the particle size, composition and reactivity of powders.

- Particle size analysis: particle size distribution.

- Chemical analysis: Detection of contaminants and elemental composition.

- Reactivity tests: Thermal analysis to assess stability and chemical reactions.

Our state-of-the-art technical resources

The FILAB laboratory boasts a full range of state-of-the-art equipment, enabling precise, in-depth analysis of materials.

Our equipment includes:

Spectroscopy (FTIR, UV-visible, Raman) for identification and quantification of chemical components.

Electron microscopy (SEM, TEM) for detailed observation of structures on a microscopic scale.

Thermogravimetric and calorimetric analysis to study material behavior as a function of temperature.

X-ray diffraction to identify crystalline phases.

Thanks to these technical resources, we are able to carry out reliable, detailed analyses that meet the requirements of the most demanding industrial sectors.

Whether it’s a one-off analysis or long-term support, we’re here to help you meet all your materials-related challenges.

FAQ

Our materials laboratory is equipped to analyze a wide range of materials, including metals, nanomaterials, polymers, composites, ceramics, glass, and powders. We offer customized services for each material type based on your specific needs.

The duration depends on the material type and the complexity of the requested tests. Generally, our turnaround times range from a few days to several weeks, balancing speed with high-quality analysis.

Our laboratory can address various industrial issues such as metal corrosion, polymer aging, composite delamination, ceramic fragility, and more. By thoroughly analyzing materials, we identify failure causes and propose tailored solutions to enhance product durability and performance.