How did FILAB help one of its customers understand a stainless steel rouging phenomenon?

With its excellent properties, stainless steel has become indispensable in many fields: everyday objects, medicine, surgery, automotive, aeronautics, mechanical industries, etc. However, many industrial stainless steel installations are affected by the phenomenon of rouging. Detectable to the naked eye, it is characterized by discoloration of the internal surfaces of certain equipment. Its color varies from yellow to black, orange, and red, depending on the severity of the phenomenon.

In the context of drug manufacturing, our client encountered rouging problems on one of its cleaning lines. Brown/red discoloration was found on the walls of its stainless steel tanks and in the process water (creating a deposit on the water line). After initial internal investigations, FILAB was called in to understand the origin of the phenomenon.

Comparative studies: an essential methodology

In the context of rouging phenomena, it is very beneficial, when possible, to perform a comparative analysis. In this case, the study was conducted between two cloths to determine the chemical nature of the deposit from a sample. This makes it possible to identify the origin of the phenomenon more quickly. In this case, our client was able to recover the deposit on a cloth and provide us with a cloth soaked in water and a reference cloth.

The techniques used to carry out this study were:

- Field emission scanning electron microscopy coupled with an EDX microprobe (SEM/FEG-EDX) to perform observations and semi-quantitative local chemical analysis.

- Fourier Transform Infrared Spectroscopy (FTIR) between 4000 and 600 cm-1 to determine the chemical nature of the bonds constituting the sample.

These two analytical methods concluded that the presence of iron particles on the soaked cloth could be responsible for the brown/red discoloration, which could explain this rouging phenomenon.

A combination of several techniques is often necessary to understand a phenomenon.

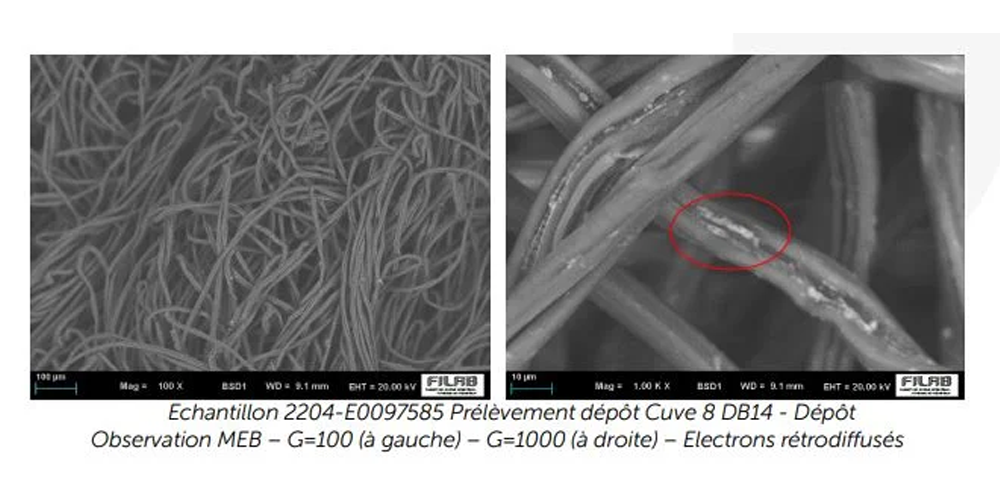

Iron (Fe) is present, corresponding to the white deposit in the image on the right above (red circle). This element is potentially in an oxidized form.

Observation of a cloth soaked in FEG-SEM

In addition to the results obtained

In addition to the results obtained by SEM-FEG and EDX analysis, Fourier Transform Infrared Spectroscopy (FTIR) analysis were performed. It appears that no infrared signal specific to the deposit recovered on the cloth was observed. This confirms its metallic nature.

Why FILAB?

With significant experience in implementing rouging analysis techniques and developing specific analysis methods, the FILAB laboratory can assist you with your needs:

- expertise in degradation following rouging,

- technical recommendations

- material selection to help you control the service life of your products or facilities,

- corrosion resistance testing

- impurity analysis in accordance with ICH Q3D