How FILAB helped one of its customers understand the yellowing of a silicone compound.

Silicones are now widely used in various fields thanks to their remarkable physical and chemical properties, such as excellent thermal stability, high resistance to oxidation and hydrolysis, and excellent gas permeability. Finally, their non-toxicity and chemical inertness allow many types of silicones to be used in cosmetics, dentistry, medicine, surgery, pharmacy, and the food industry.

As part of its component molding process for medical applications, our client encountered yellowing problems in a batch of material used on several pieces of equipment, a phenomenon that worsened during oven recoking. After initial internal investigations, FILAB was called in to understand the cause of the phenomenon.

Comparative studies: an essential methodology

When investigating failures, it is very helpful, where possible, to be able to compare the non-compliant sample with a compliant sample, i.e., one on which no degradation has been observed. This makes it possible to identify the source of a defect more quickly. In this case, our client was able to provide us with a sample from a compliant batch and then one from a non-compliant batch.

The first analytical hypothesis was that external contamination had impacted the formulation of the non-compliant batch. Here, we proposed to study organic contamination by GC-MS and inorganic contamination by ICP-AES.

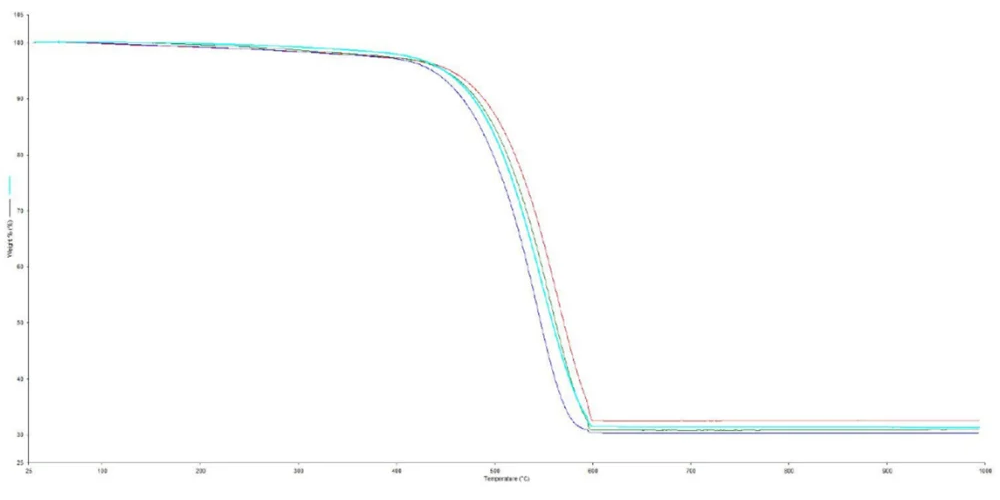

The second hypothesis was to determine the thermal properties of the two materials to find out whether the non-compliant batch could have been affected by the process temperature. The data was obtained by thermogravimetric analysis (TGA).

These first two analytical approaches concluded that the yellowing was not caused by inorganic or organic contamination, nor by different behavior of the materials with respect to temperature. However, GC-MS revealed differences in formulation that had to be validated using additional analysis.

A combination of several techniques is often necessary to understand a phenomenon

ATG spectra of the different samples

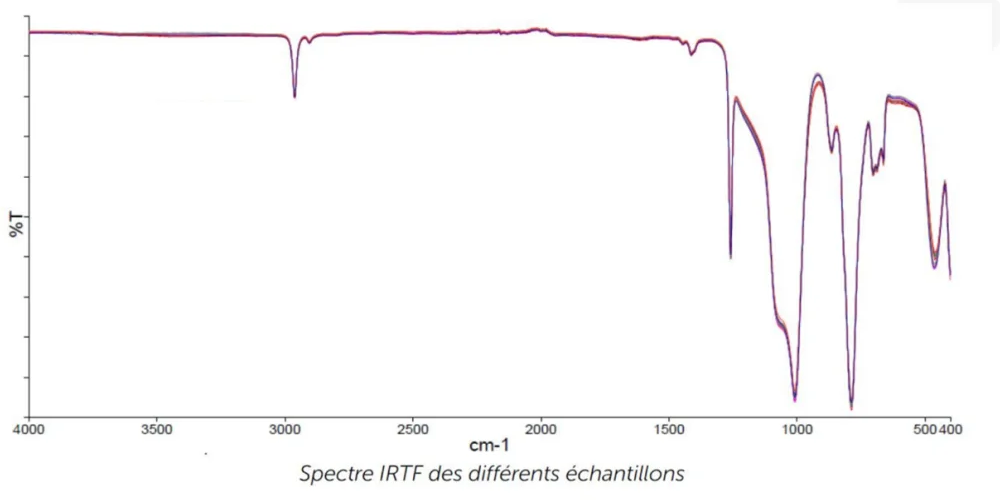

Fourier transform infrared spectrometry

Fourier transform infrared spectroscopy (FTIR) is an analytical method commonly used to study polymers. It works by identifying the chemical bonds between the atoms that make up the polymer. It can also be used to detect abnormal degradation in a material by comparing degraded and new samples, or to characterize cross-linking mechanisms.

After studying the spectra, the FTIR analysis did not reveal any significant differences in composition.

In addition to the results obtained previously, it was ultimately NMR spectroscopy, a technique that exploits the magnetic properties of certain atomic nuclei, that showed that the formulations of the two silicones were not equivalent. Here, NMR revealed, for example, that:

- The yellowing gum shows the presence of vinyl bonds, which are absent in the gum that remains white.

- The phenomenon of water absorption on the silica surface is also visible for the non-compliant sample, whereas it is not visible for the compliant silicone.

- The presence of higher quantities of carbon also probably contributes to the yellowing.

- Finally, silicon is more present in the non-compliant batch.

Why FILAB?

FILAB has extensive expertise and silicone characterization techniques tailored to a variety of needs, such as:

- Deformulation of unknown silicones

- Study of silicone thermal behavior using DSC or TGA

- Searching for impurities in silicone oils or fluids

- Expertise in silicone failures: odor, color, contamination, degradation issues, etc.