The analysis of rupture - a specialty of the FILAB laboratory

Fracture analysis is an approach that encompasses the study of causes, mechanisms and consequences of a material or structure rupture. Fracture analysis uses fractography data, but it also incorporates other types of information such as material properties, service conditions, part design, applied stresses, and mechanical test results. The purpose of this analysis is to understand not only how the rupture occurred, but also why it occurred in the specific context of the application of the material or part.

You want to perform a rupture analysis in the laboratory?

What is the breakdown of a material?

The rupture of a material occurs when the applied force exceeds the resistance of this material. This resistance can be influenced by many factors such as temperature, or the chemical composition of the material, or a failure.

Different types of fracture can be observed depending on the nature of the material and how the force is applied. For example, some materials may undergo a ductile rupture, where they deform considerably before breaking, while others may undergo a brittle fracture, where they break without significant deformation.

FILAB supports manufacturers in the expertise and analysis of rupture

Our laboratory breakdown analysis services

Material breakage is a major issue for many industries, such as aeronautics and automotive. To enable a precise analysis of the causes of ruptures, FILAB offers its expertise in fracture analysis, thanks to cutting-edge techniques and a team of experts.

- Analysis of fracture on metal part

- Analysis of rupture on polymers

- Fracture facies analysis by SEM EDX

- Fracture analysis on composites and glass

Our technical means for fracture analysis

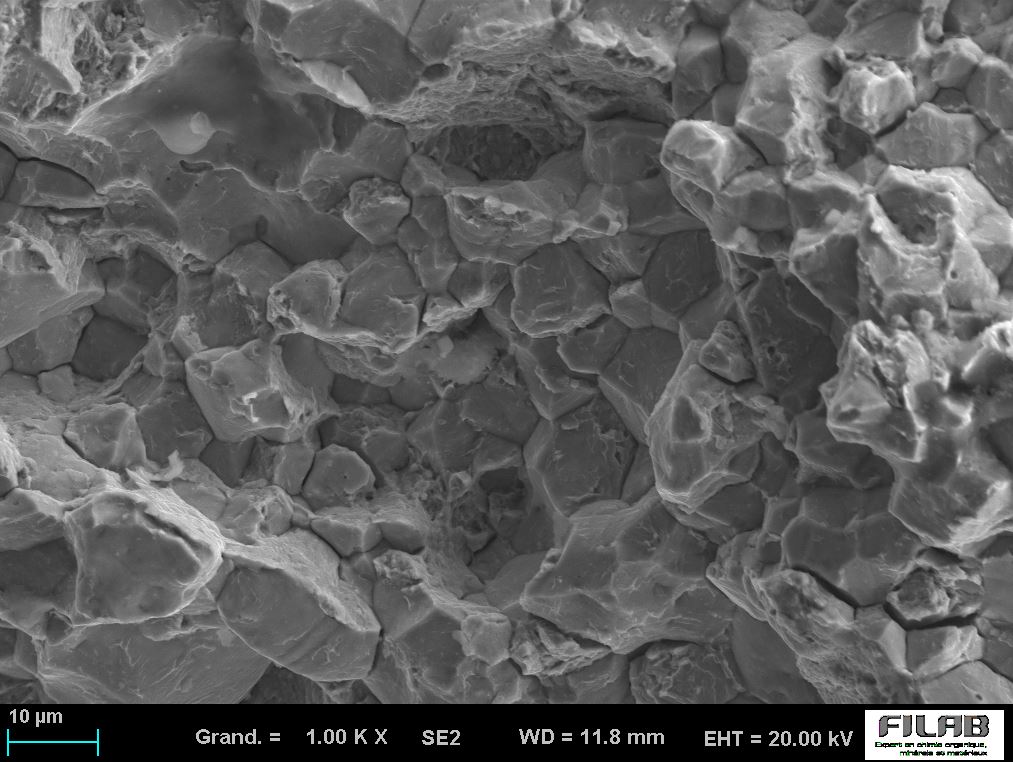

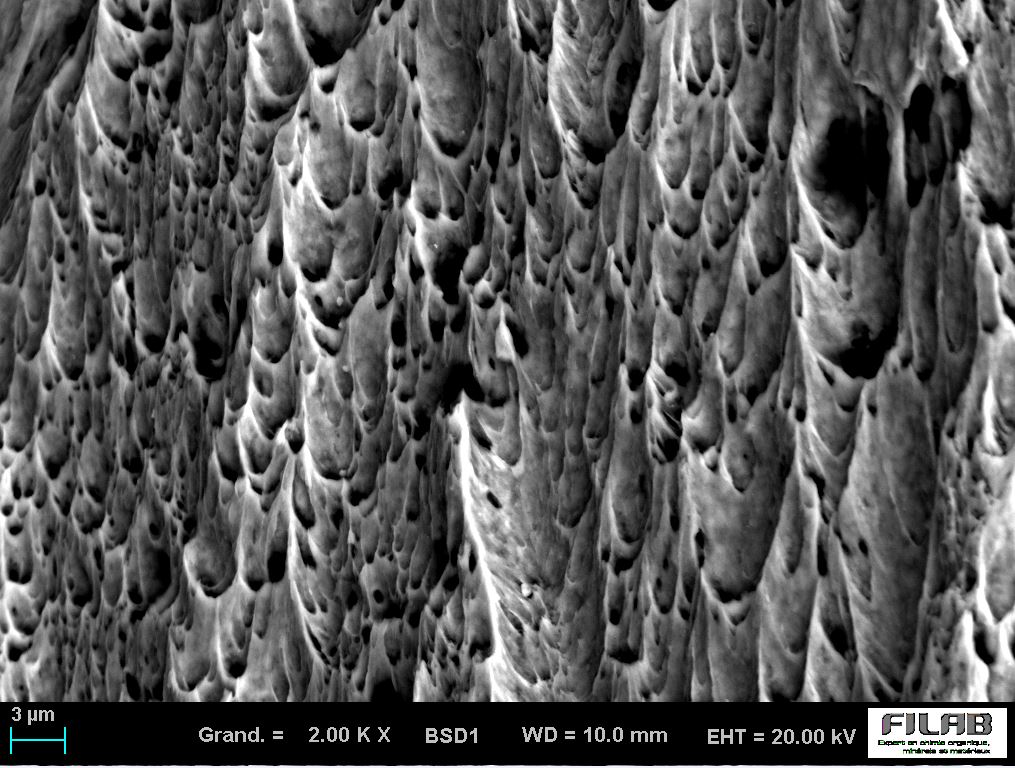

These rupture analysis examinations are carried out by scanning electron microscopy coupled with an EDX microprobe, a true cutting-edge tool requiring specific know-how of implementation but above all interpretations by our experts. It can be supplemented by micrographic observations in optical microscopy, hardness measurements, mechanical tests (tensile, resilience,...) to refine the diagnosis and increase the relevance of conclusions on the phenomenon of rupture.

Finally, the FILAB laboratory may be required to confirm the grade of the metal part broken by ICP-MS, ICP-MS-MS or ICP-AES in order to ensure its compliance with the technical specifications required by our customers.

The causes of a part rupture

In the context of industrial production, the breakage of a material or manufactured part can have significant economic and human consequences. There are many causes of material failure, ranging from the quality of materials used to the production methods implemented to the environment:

Each material has properties that influence their behaviour during breakage. The FILAB laboratory performs fracture analyses on different materials: metallic materials, polymers, composites, glass. Specifically: steel, iron and aluminum, plastic and rubber.

Sophisticated technical means are used to simulate the phenomena of rupture and thus allow to design more robust and durable parts. Indeed, composite parts, made up of several layers of materials, can break in a complex and gradual way, with the propagation of cracks. Plastic parts, on the other hand, are more likely to deform before breaking. Finally, metal parts tend to deform plastically before breaking suddenly.

The analysis of fracture for metal parts

Among the failures studied daily by our experts, the analysis of metal parts failure is an investigative context that our customers are regularly confronted with. It requires the implementation of a methodical process in order to achieve an effective diagnosis.

Step 1: Preliminary data collection

If the collection of available information on the rupture is useful (nature, material certificate, assembly information,…), knowledge of the conditions under which the rupture occurred is strategic. Isolated or not, occurrence during the production process or once the market is made… The more accurate these data are, the more effective the interpretation of analytical results and the more relevant conclusions on the origin of the rupture.

Step 2: understanding the origin of the phenomenon

The characterization and analysis of ruptures usually begins with a visual examination. This examination allows to assess the geometry of the part in general but also the morphology of the fracture zone (shape, relief, symmetry or not of the degradation…).

These first analyses are completed by a specific and thorough observation of the fracture face which constitutes a real open book on the stresses observed by the part causing the mechanical failure.

This fractographic expertise allows in particular to locate the beginning of the rupture, to identify the mode of fracture (ductile or fragile respectively in the presence or absence of deformation, static or dynamic fatigue, …). It also allows to highlight the possible presence of health defects of the material or external stresses that may be the cause of the rupture.

Some examples of applications carried out by the FILAB laboratory around fracture analysis

High-voltage electrical cable break expertise

Study of broken metal washers

Fracture examination on mechanical tensile specimen

Fractography of a broken mechanical shaft

Our mechanical analysis services

The FILAB Laboratory offers its services for other types of mechanical analyses:

FAQ

It is important to consider potential fracture risks when selecting and using different materials in order to ensure the safety and effectiveness of structures and products.

Materials that may present a risk of fracture include:

Metals and Alloys: Steel, aluminum, titanium, often used in construction, aerospace, and automotive. They may break due to fatigue, corrosion or manufacturing defects.

Ceramics and glass: Used in industrial and domestic applications. These materials are fragile and can break under mechanical stress or thermal variations.

Plastics and polymers: Used in a variety of applications, from packaging to aerospace components. They can degrade under the influence of UV, heat or chemical reactions, leading to a loss of resistance.

Composites: Composite materials used in automotive or aerospace applications, for example, can be subject to breakage under excessive loads or impact.

It is important to note that the probability and nature of the rupture depend not only on the type of material, but also on its use, environment, and maintenance.

To prevent material breakage, it is essential that appropriate preventive and maintenance measures are in place. Some actions to be implemented include:

- Material selection: Select the most suitable material according to the application, environment and the stresses it will be subjected to. This involves taking into account properties such as strength, ductility, resilience, corrosion resistance, and extreme temperature resistance.

- Accurate design and engineering: Ensure that the design of parts and structures is optimized to distribute loads evenly and minimize concentrated stress points.

- Quality control and regular testing: Perform rigorous quality controls during manufacturing and regular testing. This may include fatigue testing, visual inspections.

- Protection from harsh environments: Apply coatings, paints, or other forms of protection to reduce the impact of exposure to corrosion, moisture, chemicals, or UV radiation.

- Compliance with standards and regulations: Comply with industry standards and applicable regulations, which are often based on extensive research and feedback to ensure the safety and reliability of materials.

By following these practices, the risk of material breakage can be significantly minimized.

Fracture analysis and fractography are used to understand the causes of material failure. The first analysis consists of examining the surfaces of a part to determine the characteristics of the fracture and identify potential defects in the material. Fractography allows a more detailed analysis of the crystal structure of the broken piece. Various technical means are available to analyse the rupture of a material.

- Microscopy allows the observation of faults at a microscopic scale, which gives indications on the nature of the rupture.

- Tensile tests, which involve applying a tensile force to the material until it breaks, are also very common.

- The bending tests are used to measure the resistance of a material to bending.

- 3D tomography is useful for analyzing internal material deformations before and after the rupture.

- Numerical simulations are used to help understand the rupture at the macroscopic level.

All these techniques, combined with each other, allow to have a global and precise vision on the process of material rupture, and thus measure the limits of resistance of a material and prevent potential ruptures.

Fractography is the study of material fracture surfaces, which focuses on examining the topography of the fracture surface to determine the cause and mode of rupture. This is usually done using scanning electron microscopy (SEM), to observe the microscopic characteristics of the fracture surface. It allows to identify phenomena such as fatigue, fragility, ductility, inclusions and other material defects, depending on the observed fracture facies. In summary, fractography is a specificity of the rupture analysis, focusing specifically on the detailed examination of the fracture surfaces, While the fracture analysis is a more comprehensive study of the causes and circumstances surrounding the rupture of a material or structure.