Laboratory analysis by RAMAN Spectroscopy

You would like to carry out a RAMAN spectroscopy analysis to identify the chemical and molecular composition of your materials and products

What is a RAMAN analysis?

Raman spectroscopy analysis is a non-destructive analytical technique used to identify the chemical composition and molecular structures of a sample.

The method is based on the inelastic scattering of light (Raman effect) when a laser interacts with the molecules in the sample.

Raman spectroscopy is particularly popular for the analysis of organic and inorganic materials, and for the study of complex substances without the need for specific sample preparation.

Unlike other techniques such as FTIR, Raman spectroscopy can be used to analyse symmetrical bonds that are difficult to detect in other ways, making it more complementary in many industrial and scientific contexts.

What are the advantages of Raman analysis?

The Raman spectroscopy analysis technique offers a number of advantages:

- It allows precise identification of the chemical compounds in a sample, including those present in small quantities.

- This is a non-destructive analysis technique that allows samples to be analyzed without damaging them.

- It can be used on many types of samples: solid, liquid or gaseous.

- It provides comprehensive information on both molecular structure and the dynamics of chemical bonds.

When should Raman spectroscopy be preferred to FTIR spectroscopy?

Raman spectroscopy is recommended in the following cases:

Analysis of carbon bonds in aliphatic or aromatic rings.

Analysis of carbon bonds in aliphatic or aromatic rings.

Study of bonds that are difficult to identify with FTIR, such as 0-0, S-H, C=S, N=N, C=C

Study of bonds that are difficult to identify with FTIR, such as 0-0, S-H, C=S, N=N, C=C

Examination of particles in solution to explore polymorphism

Examination of particles in solution to explore polymorphism

Analysis of low-frequency modes, for example in inorganic oxides

Analysis of low-frequency modes, for example in inorganic oxides

Study reactions in aqueous media, where FTIR is less suitable

Study reactions in aqueous media, where FTIR is less suitable

Observation of complex reactions requiring analysis through windows (high-pressure catalytic reactions, polymerisations)

Observation of complex reactions requiring analysis through windows (high-pressure catalytic reactions, polymerisations)

Analysis of three-dimensional networks at low frequency

Analysis of three-dimensional networks at low frequency

Monitoring two-phase and colloidal reactions to identify triggers or end points

Monitoring two-phase and colloidal reactions to identify triggers or end points

FTIR spectroscopy is preferable for :

Liquid phase reactions

Liquid phase reactions

Samples with reagents, solvents or fluorescent species that interfere with Raman

Samples with reagents, solvents or fluorescent species that interfere with Raman

Bonds where dipolar modifications are important, such as C=O, O-H, N=O

Bonds where dipolar modifications are important, such as C=O, O-H, N=O

Reactions where the reagents are poorly concentrated

Reactions where the reagents are poorly concentrated

Cases where the Raman spectrum is disturbed by dominant solvent bands

Cases where the Raman spectrum is disturbed by dominant solvent bands

Observation of infrared-sensitive intermediates

Observation of infrared-sensitive intermediates

The complementary nature of the two techniques makes them powerful and indispensable tools in chemical and industrial analysis.

The principles of Raman analysis

Raman analysis is a non-destructive spectroscopic technique using a laser as the light source. The resulting Raman spectrum, showing the intensity of light scattered at different wavelengths, is analyzed to identify the compounds present. Each substance has a characteristic Raman spectrum due to its chemical bonds and molecular structure.

The Raman technique can be applied to a variety of samples, including solids, liquids and gases, and test conditions can be adapted, such as temperature and pressure.

Raman spectroscopy offers a unique ability to detect subtle variations in molecular structures and chemical bonds, revealing information invisible to other methods.

Why carry out a RAMAN analysis?

Raman analysis aims toidentify the chemical composition of samples and provide detailed information about their molecular structure and chemical bonds. Thanks to its sensitivity to different molecular configurations, Raman analysis is able to detect fine nuances in chemical composition, providing an in-depth understanding of the physical and chemical properties of the materials studied.

FILAB laboratory is able to assist industrialists with their various problems by providing RAMAN Spectroscopy analysis services

Whatever your industrial sector (Chemicals, Pharmaceuticals, Cosmetics, Food) or the application of your products, FILAB ‘s RAMAN analysis expertise and services will enable you to analyze even small areas of contamination. This technique can also be used to identify materials and measure stresses.

Raman spectroscopy is also essential for in situ analyses, such as monitoring chemical reactions, understanding reaction mechanisms or assessing materials subjected to thermal or mechanical stress.

Our equipment includes advanced spectrometers with adjustable lasers (532, 785 and 1064 nm), guaranteeing increased sensitivity even in complex analytical environments.

Our technical resources: RAMAN

Raman analysis, as a method of spectroscopy, is a cutting-edge method characterised by several technical aspects.

It uses a high-intensity laser, whose interaction with the sample causes light to be scattered. Most of this light is scattered elastically, known as Rayleigh scattering, while an inelastic portion, crucial to the analysis, is known as Raman scattering. The scattered photons are analyzed by a spectrometer, which determines the intensity of the light at different wavelengths, revealing the Raman spectrum specific to the sample. In addition, the integration of Raman microscopy makes it possible to obtain detailed images of the distribution of chemical compounds on a microscopic scale.

Industrial sectors where RAMAN technology is used

The characteristics obtained make Raman spectroscopy extremely effective for chemical analysis and applicable in various fields such as materials characterization and pharmaceutical analysis.

RAMAN analysis can be used in the following applications:

- Industrial materials: In industry, it is used for quality control, detecting contaminants, or studying the properties of materials such as polymers, ceramics, etc.

- Pharmaceuticals and cosmetics: Raman spectroscopy is used to analyse the composition and verify the quality of drugs and cosmetics.

In short, Raman analysis is favoured for its versatility, its ability to provide detailed information without damaging the sample, and its applicability to a wide range of materials in different fields.

Surface inspection of a material

Analysis of microplastics in water using RAMAN Spectroscopy

Identification of chemical composition

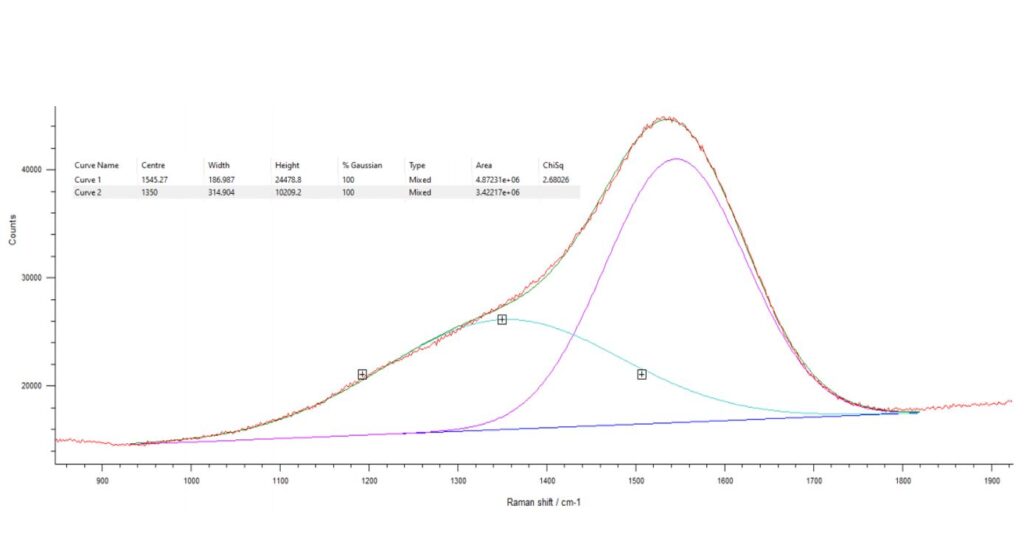

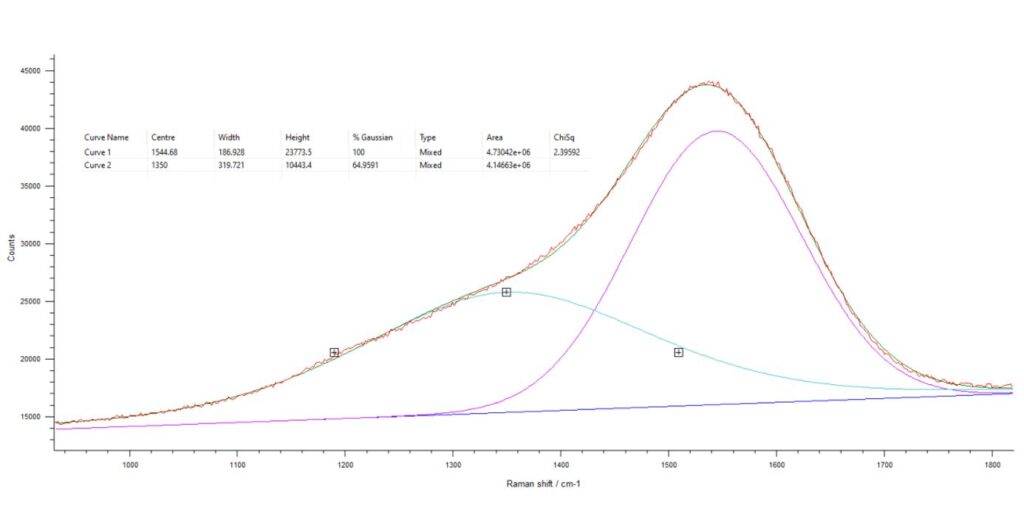

Study of the presence of graphene in surgical masks using RAMAN spectroscopy

FAQ

Raman spectroscopy is an analytical technique used to identify and characterise molecules. It measures changes in the inelastic scattering of monochromatic light, i.e. when a photon interacts with a molecule and causes it to vibrate. This interaction produces an optical signal that contains information about the molecular structure, such as bond strength, molecular symmetry and conformation. By deciphering this signal, Raman analysis obtains information about the composition of the sample being analyzed.

Raman spectroscopy has become increasingly important for many different applications due to its ability to provide rapid and reliable analysis without damaging or altering samples, making it ideal for life science research and quality control and assurance testing in industry. The technique also provides information on the crystallinity, purity, phase and homogeneity of the sample. By combining various spectroscopic techniques such as infrared spectroscopy, X-ray diffraction and thermogravimetric analysis with RAMAN spectroscopy, researchers can obtain more detailed structural information about the analyzed sample. RAMAN analysis is a powerful tool for research in fields such as materials science and biochemistry. In addition to laboratory applications, Raman spectroscopy is also used for clinical diagnosis and space exploration.

Raman spectroscopy is also advantageous because of its portability; it requires minimal sample preparation compared to other analytical techniques and can be performed using portable instruments. It is therefore ideal for field work or on-site measurements, as the standard operating conditions are very good.

Raman spectroscopy plays an important role in many industries and can be used to analyse a wide range of sample types. Industries such as pharmaceuticals, food and beverage, cosmetics, materials science and biochemistry are just some of the areas that benefit from this technology. Raman analysis allows researchers to quickly identify unknown compounds or confirm molecular structures in a variety of samples. Raman spectroscopy is useful for characterising catalysts and studying chemical reactivity. Its portability makes it ideal for field work or on-site measurements. The use of Raman spectroscopy in quality control and quality assurance testing has increased dramatically in recent years due to its accuracy, reliability and cost effectiveness.

Raman spectroscopy is based on the inelastic scattering of monochromatic light. When a sample is illuminated by a laser beam, certain particles interact with the molecules present and cause them to vibrate. This vibration produces an optical signal that contains information about the molecular structure. By analysing this signal, it is possible to obtain information about the composition and properties of the sample being analysed. The Raman spectrum produced by this process can be used to identify unknown compounds or confirm molecular structures. The use of filters and software algorithms allows weak signals to be amplified and background noise to be reduced, leading to more accurate results. Finally, data analysis techniques such as principal component analysis are used to interpret complex Raman spectra.

L'analyse Raman est largement utilisée dans le secteur pharmaceutique pour ses capacités de caractérisation rapide et non destructive. Voici ses principales applications :

> Identification des matières premières : Pour assurer la qualité des médicaments.

> Contrôle de qualité : Détecte les impuretés et confirme la composition chimique des produits finis.

> Analyse des formes posologiques : Examine la distribution des ingrédients actifs dans diverses formes comme les comprimés et les gélules.

> Développement de formulations : Optimise les formulations en analysant les interactions entre composants.

> Étude de la stabilité : Surveille les changements chimiques des médicaments sous différentes conditions de stockage.

Ces utilisations font de l'analyse Raman un outil essentiel pour améliorer la sécurité et l'efficacité des produits pharmaceutiques.

Raman analysis is highly versatile and can be carried out on a wide variety of samples and materials in many fields:

- Crystals and minerals: Used to study crystal composition and structure.

- Pharmaceuticals: As mentioned above, for raw material identification, quality control and dosage form analysis.

- Polymer materials: Analysis of the chemical and structural properties of plastics and other polymers.

- Nanomaterials : Assessment of the composition and properties of nanotubes, nanoparticles, etc.

- Semiconductor materials: Analysis of the structure and defects of materials used in electronics.

- Chemicals: Monitoring of chemical reactions, identification of pure chemical compounds or mixtures.

Thanks to its non-destructive approach and its ability to provide detailed information on chemical composition, Raman spectroscopy is applicable to almost all types of materials.

Raman analysis on metals is possible but complex due to the specific optical characteristics of these materials. Metals reflect light strongly, which can be problematic for Raman spectroscopy as much of the laser radiation used is reflected back rather than scattered in a way that is useful for analysis.

In addition, metals tend to produce a strong fluorescence signal when exposed to the laser, which can mask the often weaker Raman signal. Another problem is localised heating of the sample due to laser absorption, which can alter the results of the analysis. Despite these challenges, specific techniques and instrument configurations can be used to minimise these effects and enable efficient Raman analysis of metallic samples.

The choice between Raman spectroscopy and FTIR depends on the sample and the type of analysis. FTIR is best suited to polar materials such as proteins and plastics with O-H bonds, but water can interfere. Raman is ideal for non-polar substances, carbon structures (graphite, graphene), and polymers, and allows analysis of aqueous samples without complex preparation.

- Raman spectroscopy is a non-destructive analysis technique used to study the chemical and structural composition of materials by measuring the inelastic scattering of light, known as the Raman effect.

- Raman spectrometry is used to perform quantitative analyses to measure the concentrations of components present in a sample.

- Raman microscopy is used to create detailed chemical maps on a microscopic scale, useful for studying complex samples such as composites, polymers or nanomaterials.

Raman spectroscopy is based on the principle of inelastic light scattering, known as the Raman effect. When a monochromatic laser beam is directed onto a sample, most of the light is elastically scattered (Rayleigh scattering) without any change in energy. However, a small fraction of the light interacts with the molecular vibrations of the sample, causing a slight energy shift in the scattered light. These energy shifts correspond to the specific vibrations of the chemical bonds in the molecules, making it possible to construct a unique spectrum for each material. This non-destructive method is invaluable for identifying chemical composition, studying molecular structures and analysing a variety of materials, such as polymers, crystals, and organic and inorganic compounds.

Raman spectroscopy is used in a variety of industrial contexts and sectors because of its ability to provide detailed, non-destructive information about the chemical composition and molecular structure of materials.

In the pharmaceutical industry, it is used for analysis of active ingredients and quality control of drugs.

In the materials sector, it is used to study polymers, composites and nanomaterials to check their uniformity and properties.

The petrochemical industry uses this technique to analyse hydrocarbons and catalytic reactions.

Raman spectroscopy addresses a range of industrial problems, providing precise quality control and detecting impurities, particularly in the pharmaceutical and cosmetics sectors.

It checks the homogeneity of materials, studies composites and nanomaterials to optimise their properties, and characterises chemical reactions in the development of new products.