You would like to carry out an SEM-EDX analysis in the laboratory

The principles of SEM-EDX analysis

SEM (Scanning Electron Microscopy) analysis coupled with EDX (Energy Dispersive X-ray Spectroscopy) is a powerful technique used in the laboratory to study the morphology and chemical composition of samples. The main principles of SEM-EDX analysis are :

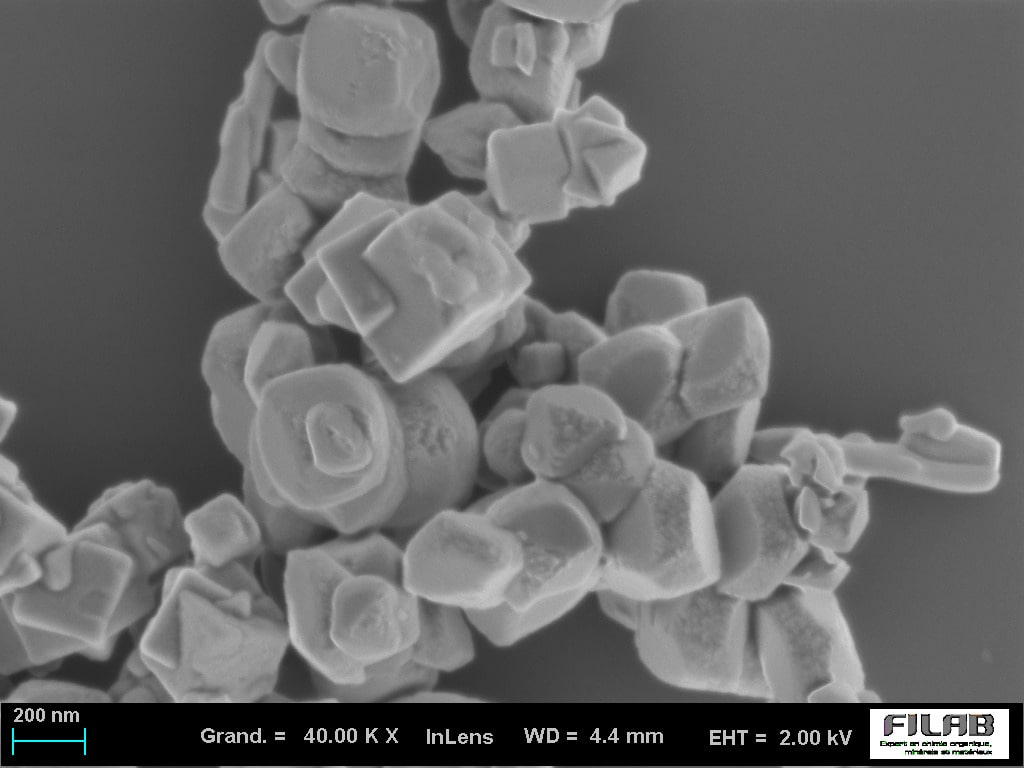

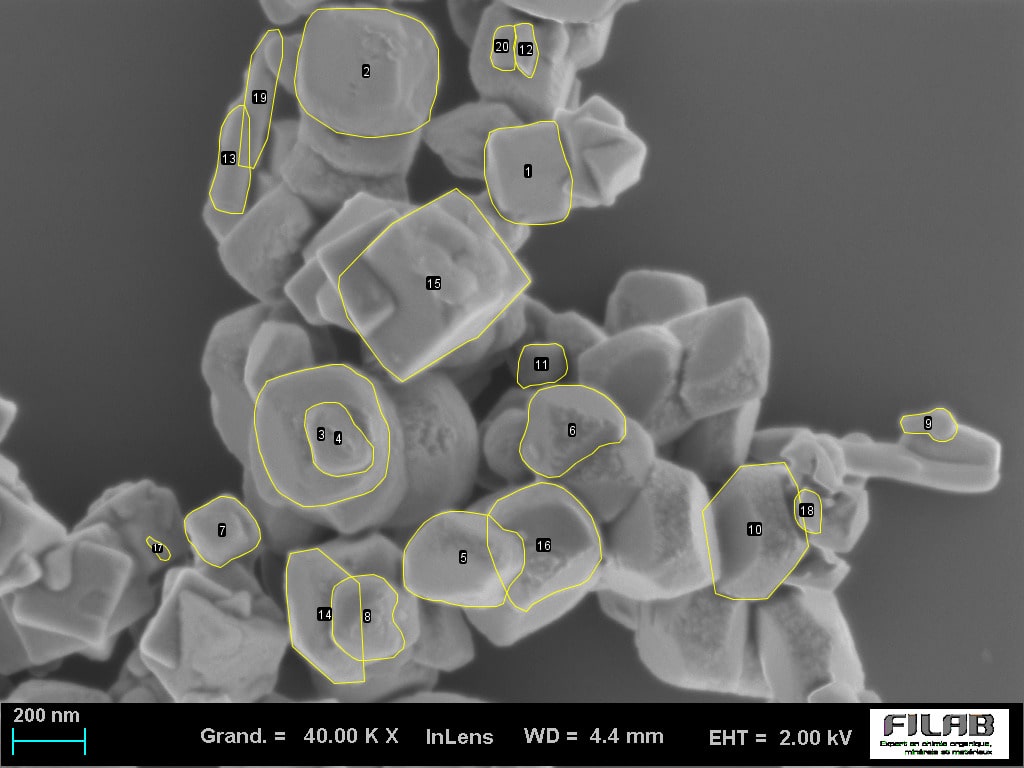

SEM uses a beam of electrons scanned over the sample to produce an image of its surface, revealing the topography, morphology and sometimes the chemical composition of the sample's surface. The high resolution of the SEM makes it possible to observe details on a nanometric scale.

EDX is often used in conjunction with FEG SEM. When the electron beam from the SEM strikes the sample, it excites the atoms, causing them to emit characteristic X-rays. Analysis of these X-rays can identify the chemical elements present in the sample and, in some cases, provide a quantitative dimension.

Our SEM-EDX laboratory analysis solutions

The FILAB analysis laboratory is now one of the first laboratories in France to be equipped with 3 SEMs.

This microscopic SEM analysis tool is particularly powerful and efficient for rapid diagnosis (pollution, inclusion, etc.) or more complex expert assessments.

Our technical resources: SEM-EDX (SEM-FEG, SEM Tungsten and SEM-EBSD)

In the FILAB laboratory, the SEM-EDX is the primary diagnostic tool. This is why we have chosen to include :

Two FEG-SEM coupled with an EDX probe for assessing material failure (metals, polymers, ceramics, glass, etc.) and R&D.

A Tungsten SEM coupled to an EDX probe for identifying particles, contaminants, deposits and pollution.

The SEM makes it possible to study different surfaces very precisely, thanks to its ultra-high-definition image resolution.

A variable pressure (VP) mode for insulating samples for non-destructive analysis of all types of materials (without metallisation)

A sensitive and fast 80 mm² energy dispersive microprobe (EDS) for semi-quantitative chemical analysis and mapping, including light elements

An In-Lens detector for very high resolution images of the order of 1 nm with acceleration voltages of around 1 kV

A transfer airlock for the rapid and clean introduction of ‘large’ samples

Other technical resources: SEM and analytical coupling

The FILAB laboratory has a range of technical resources for chemical analysis. Analytical coupling of SEM (Scanning Electron Microscope) with other analytical methods, such as SEM-EDX, provides detailed information on the chemical composition, crystal structure and morphological properties of the samples observed. In this way, coupled SEM offers comprehensive characterization on a microscopic scale.

Our expertise in SEM EDX and SEM FEG

Our SEM-EDX expertise is fundamental to our analytical approach. At FILAB, our team of experts uses SEM EDX analysis to address complex analytical challenges, providing our customers with reliable, high-quality results on a variety of performance types:

Inspecting for failure

Identification of particles, contaminants and deposits

Nanometric characterisation: FILAB is the first French laboratory to be COFRAC ISO 17025 accredited in this field.

Why perform an SEM EDX analysis?

The combination of SEM images and EDX data provides a wealth of information on the sample, from material characterization to failure analysis. The results can reveal information on crystal structure, phase composition, elemental distribution and other important properties of the samples studied, in the context of chemical analysis.

SEM-EDX (Scanning Electron Microscope) expertise: what are we talking about?

Scanning Electron Microscopy (SEM-EDX) is a laboratory microscopic analysis technique using a Field Emission Gun (FEG). This technique produces very high resolution images of the surface of a sample (magnification of the order of *1000000). It is a technique used to study the chemical composition and morphology of solid materials. The FILAB laboratory specialises in SEM-EDX expertise.

That's why the FILAB laboratory has decided to equip itself with not one, but 3 SEMs! All three are also equipped with EDX probes for extremely precise analysis of your materials. These SEM-EDX techniques, with a column signal detection 20 times more intense than that of a conventional Scanning Electron Microscope, enable the FILAB laboratory to carry out high added-value analyses. We obtain clear images for non-destructive, accurate and much faster observations and investigative analysis.

Industrial sectors of application of the MEB-EDX technique :

The MEB-EDX or MEB-FEG-EDX technique can be applied to all areas of industry, depending on the results required:

Luxury goods (Jewelry, Horology, Leathercraft…)

FAQ

SEM-EDX analysis is a microscopy technique used for imaging and analysis of elements and chemical composition. This technique combines scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX). SEM-EDX analysis allows the surface structure and chemical composition of materials to be observed at high magnifications. The combination of these two techniques allows a detailed study of individual particles and surface characteristics of the material, which can be as small as 1 nanometre. The analytical information obtained from this analysis can provide valuable insights into the properties and characteristics of the sample in question. In addition, it can be used to identify contaminants or other impurities that may be present in trace amounts. SEM-EDX analysis is often used in a wide variety of applications, including materials science and forensic analysis. With this advanced technique, researchers can obtain precise information about the chemical composition of samples on a very small scale.

The SEM EDX analysis process begins by placing the sample in the chamber of an electron microscope. The electrons emitted from the sample then pass through an energy filter to produce secondary X-rays which are detected by the EDX detector. The energy dispersed X-ray data is then analysed to determine the composition and concentration of elements present in the sample. This analysis can provide accurate results on particle size distribution, crystal structures, oxidation states and other characteristics of individual particles.

SEM-EDX analysis is used in a wide range of industries including materials science, aerospace engineering, medical research, electronics manufacturing, environmental studies and forensic analysis. SEM analysis can be used to analyse and identify contaminants or other trace impurities in materials and components. It can also help researchers to better understand the surface characteristics of materials, such as particles or nanoscale structures. In addition, SEM-EDX analysis can provide valuable information on the composition and concentration of elements present in samples for a variety of applications. In addition, this microscopy technique has been successfully used by the pharmaceutical industry to detect active ingredients in drug samples with high accuracy.

EDX analysis (Energy dispersive X-ray (EDX) analysis) or EDX-analyse is performed using an EDX probe. This is a spectroscopic instrument, using X-rays to explore the chemical properties of elements present in a material. Combined with other complex material failure analysis techniques, EDX probes help analysts to understand the cause of material deterioration, and to develop appropriate solutions to prevent such material failures. Laboratories such as FILAB offer in-depth material failure analysis using EDX analysis equipment..

The EDX probe or EDX detector receives photons emitted by the material following electronic excitation by a special device. The EDX probe then measures the energy generated by the material. Each chemical element has a characteristic energy value, making it possible to identify the elements contained in the material.

This technology is very useful for characterizing the properties of materials, for example, to determine their composition, purity or concentration of specific elements. It is therefore the tool of choice in our laboratory for accurate and reliable analysis of materials.

SEM-EDX analysis can provide several types of information relating to materials and surface characterization :

- Imaging: scanning electronic microscope provides detailed images of the sample surface, revealing its topography and structure on a microscopic scale.

- Elemental composition: Energy Dispersive X-ray Spectroscopy (EDX-analyse)determines the chemical elements present in the sample, and their relative quantities. This makes it possible to identify the constituent elements of a material, or to detect the presence of specific elements.

- Elemental mapping: SEM-EDX analysis can also generate elemental distribution maps in the sample, enabling the spatial distribution of chemical elements to be visualized.

EDX stands for Energy Dispersive X-ray Spectroscopy. It's a technique used for elemental analysis or chemical characterization of a sample.

EDX analysis is a technique used to determine the elemental composition of materials. By measuring X-rays emitted from a sample when bombarded by electrons, EDX identifies and quantifies the elements present. This analysis is essential for research and quality control across various scientific and industrial fields.

What are the differences between SEM EDX and EDX in terms of analysis ?

SEM-EDX combines the high-resolution imaging capabilities of Scanning Electron Microscopy (SEM) with the elemental analysis provided by Energy Dispersive X-ray Spectroscopy (EDX).

SEM focuses on generating detailed images of material surfaces up to the nanometer scale, revealing texture and morphology, while EDX characterizes the elemental composition by analyzing the X-rays emitted from the material when bombarded with electrons.

Together, SEM-EDX offers a powerful tool for simultaneously understanding both the physical structure and chemical properties of materials, important for fields like materials science and semiconductor research.

EDX analysis is a method used for identifying and quantifying the elemental composition of materials. It is applicable to a broad range of samples and materials, including:

> Metals and Alloys: EDX can determine the elemental makeup of metallic samples, useful in metallurgy for quality control, alloy development, and failure analysis.

> Semiconductors and Electronic Components: It helps in the analysis of materials used in electronic and photonic devices, checking for impurities or composition accuracy.

> Biological Samples: In biology and medicine, EDX can be used to study the distribution of elements within tissues, cells, or bioengineered materials, often to understand physiological processes or disease mechanisms.

> Polymers and Plastics: EDX can also be used to analyze the presence of additives or contaminants in synthetic materials.

> Ceramics and Glasses: Analyzing ceramic materials or glass to determine their elemental composition, which is critical for understanding their properties and performance.

> Environmental Samples: EDX can analyze particles collected from air or water samples to identify pollution sources or environmental contaminants.

EDX is particularly valued for its non-destructive nature and its ability to perform localized analysis, providing elemental data from very small areas (micrometer scale), which is essential for materials research and quality control across these diverse fields.

Scanning Electron Microscopy (SEM) is used to examine surface morphology, microstructures, and material composition at very high resolution. It is widely applied in industries such as metallurgy, pharmaceuticals, polymers, electronics, and failure analysis.

SEM can analyze a wide variety of materials, including metals, ceramics, polymers, biological samples (after preparation), coatings, powders, and composites. Both conductive and non-conductive samples can be examined using appropriate preparation techniques.

Yes, when coupled with Energy Dispersive X-ray Spectroscopy (EDS/EDX), SEM can determine the elemental composition of the analyzed area. This is particularly useful for identifying contamination, verifying alloy structures, or detecting foreign particles.

SEM provides high-resolution images down to the nanometer scale. It allows users to observe features such as surface texture, grain structure, porosity, cracks, or coating layers, depending on the magnification and sample quality.

Yes, most samples require preparation to ensure optimal results. This may involve cleaning, drying, coating with a conductive layer (for non-conductive samples), or cross-sectioning. FILAB handles all necessary preparation in-house.

Yes, SEM is one of the most effective tools for failure analysis. It can reveal fracture patterns, material fatigue signs, contaminant deposits, or structural defects that are not visible with conventional microscopy.