Laboratory expertise of corrosion occurrence

Your needs : expertise on the occurence of corrosion

What is corrosion ?

Corrosion is the general term used to describe a chemical reaction between a material and its environment leading to the material deteriorating. This phenomenon can affect all kinds of materials but mostly metals and metallic alloys.

Why carry out a corrosion expertise?

Corrosion is a veritable industrial scourge, affecting the reliability and strength of a metal product and its structure. The presence of corrosion can also raise health and environmental safety issues.

Assessing the occurrence of corrosion is a major challenge in the industrial sector. Analysis of corrosion-related failures (leaks, ruptures, adhesion problems, etc.) by a specialist laboratory will identify the causes external to the material, so that you can adapt your activity with lasting, reliable solutions.

The effects of corrosion on a material

Corrosion can lead to a number of risks and problems for materials, structures and equipment, such as:

In order to minimise these risks and prevent corrosion phenomena, it is essential to carry out a laboratory expertise of the onset of corrosion.

Expertise in the occurrence of corrosion: FILAB's long-standing expertise

For more than 30 years, the FILAB laboratory has had the experience and specific analytical equipment to support companies in the analysis and assessment of the occurrence of corrosion, through tailor-made assistance.

Our expertise in the occurrence of corrosion

From analysis to R&D, the FILAB laboratory offers multi-sector expertise when it comes to corrosion:

- Laboratory analysis of the degree of corrosion attack on a material

- Characterization of the causes of corrosion on a material

- Analysis of corrosion precursors (halogens)

- Corrosion resistance tests (salt spray tests)

- Study of the effectiveness of an anti-corrosion system applied to the material (surface treatment, coating, paint, etc.)

- Study the effectiveness of an anti-corrosion system applied to the material (surface treatment, coating, paint, etc.)

- Expertise and advice on the choice of an anti-corrosion material or formula to control the lifespan of a product or installation in the face of potential corrosion problems.

- Help with your choice of materials depending on your applications

Our technical resources for expertise on the occurrence of corrosion

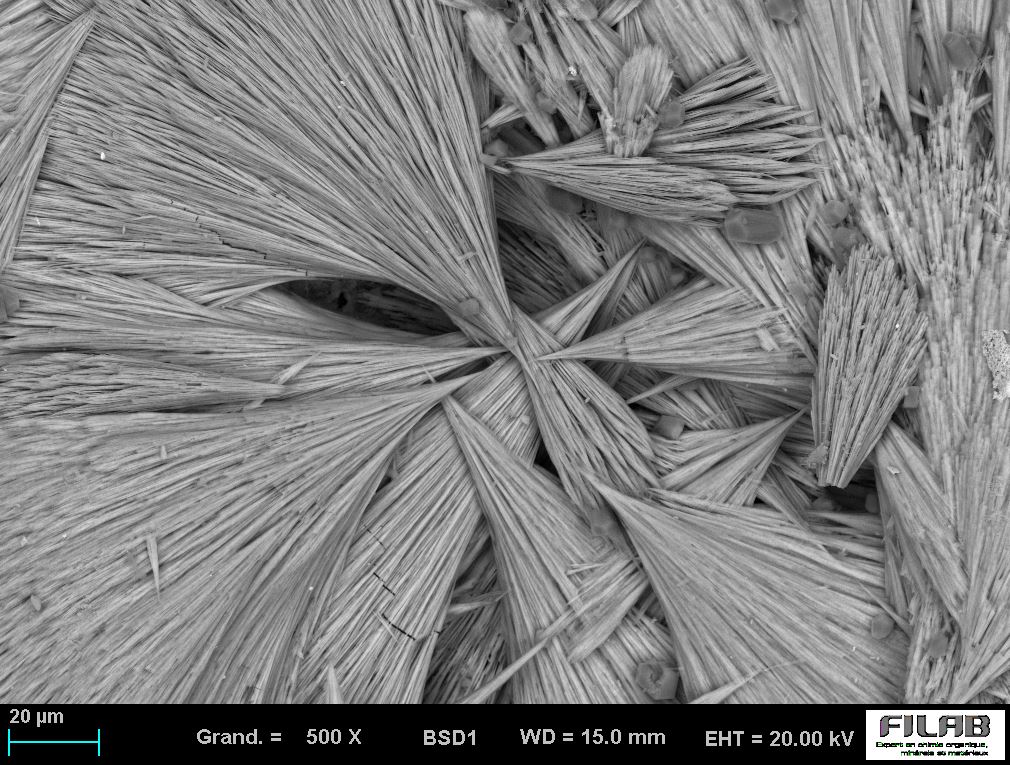

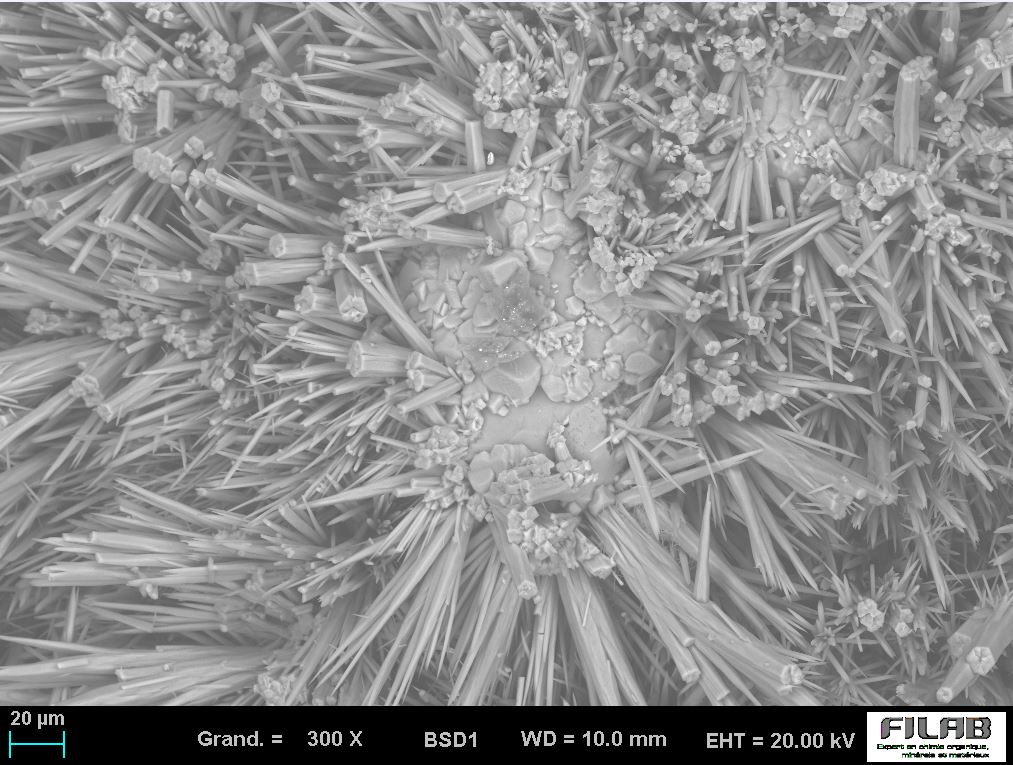

Oxides by SEM

To carry out corrosion analysis on your materials or parts, the FILAB laboratory uses a range of cutting-edge analysis techniques:

Scanning Electron Microscopy coupled to an EDX microprobe (FEG-EDX SEM), microstructural examinations (study and micrographic examination)

ICP (ICP-MS or ICP-AES)

Salt spray

BSN

MO

Consulting with an expert (understanding the environment)

XRD

XPS

Standardised corrosion resistance test (intergranular corrosion)

See more...

Study of the rouging phenomenon

A laboratory corrosion test can include different types of materials to be tested. Metals, such as steel, copper and aluminium, are frequently studied because of their frequent exposure to moisture and air. Metal products, such as galvanised steels and copper-nickel alloys, can also be evaluated for their corrosion resistance. Non-metallic materials, such as coatings, plastics and composites, can also be subjected to corrosion tests to assess their durability in the presence of corrosive liquids. In a laboratory corrosion test, various test techniques can be used to mimic real-life conditions. This makes it possible to predict how long a material will last in corrosive environments and to plan accordingly.

To prevent corrosion on steel, the application of protective coatings such as paint, galvanising or plating provides a physical barrier between the steel and corrosive agents. In addition, it is important to maintain a dry environment wherever possible, as humidity is a major factor in corrosion.

Using corrosion-resistant materials in hostile environments and designing structures to allow adequate drainage also help to prevent corrosion. Finally, regular monitoring, preventive maintenance and replacement of corroded parts are essential practices to ensure the durability of steel structures and components.

A corrosion oxidation test is a specific test designed to assess the oxidation and corrosion resistance of a material or coating by exposing the sample to severe environmental conditions. The aim of this test is to simulate the real conditions to which the material will be exposed, in particular when subjected to high temperatures and atmospheric oxygen. Corrosion oxidation testing is commonly used to assess the durability of metallic materials and coatings in exposed environments.

Corrosion is a process that can affect various materials as a result of environmental and chemical factors.

List of the main causes of corrosion on materials:

1- Electrochemical corrosion: This is the most common form of corrosion, where electrochemical reactions occur on the metallic material, due to water and ions present in the environment.

2- Oxidative corrosion: Metals react with oxygen in the air to form metal oxides, which gradually weaken the material.

3- Galvanic corrosion: This occurs when two dissimilar metals come into contact in a conductive environment.

4- Pitting corrosion: This is the formation of small holes or pits on the surface of the material, often very localised.

5- Stress corrosion: This occurs when mechanical stresses are combined with corrosive conditions, which can lead to cracking and material failure.

6- Microbiological corrosion: Bacteria, fungi and algae can colonise the surface of materials, producing corrosive chemicals.

7- Contact corrosion: Exposure to corrosive chemicals such as acids or salts can cause rapid corrosion of materials.

It is important to take these corrosion factors into account when selecting materials and designing your parts, in order to minimise the risks and ensure the durability of components and installations.

Our laboratory's expertise in corrosion occurrence can be defined by a number of criteria that demonstrate our ability to provide accurate information on corrosion processes. Here are some elements to consider when assessing our corrosion expertise:

> Certification and accreditation: FILAB meets high standards of technical competence and testing processes, according to the ISO and COFRAC standards.

> Equipment and technology: Expertise in corrosion analysis is based in part on our state-of-the-art equipment and accurate measurement technologies.

> Industry experience: FILAB has experience in specific industries, enabling us to carry out tests and analyses for the aerospace, metallurgy, automotive and other industries.

> Multiple services: we offer various corrosion analysis services, such as accelerated corrosion testing, material durability studies, corrosion-related failure analysis, and support for corrosion prevention and protection.