How did FILAB help one of its clients determine the cause of a steel piston rod breakage?

A piston is a crucial mechanical component in many mechanical devices and engineering systems. Pistons have a variety of applications, including energy conversion, pressure generation, fluid control, damping, etc.

The customer called on FILAB, a laboratory specializing in material characterization and chemical analysis, to determine the cause of the breakage of a steel piston rod. The customer first wanted to verify the grade of this part and then carry out a fractographic study.

Determination of steel grade

What analysis techniques did the FILAB laboratory decide to use to perform the chemical analysis of the faulty piston?

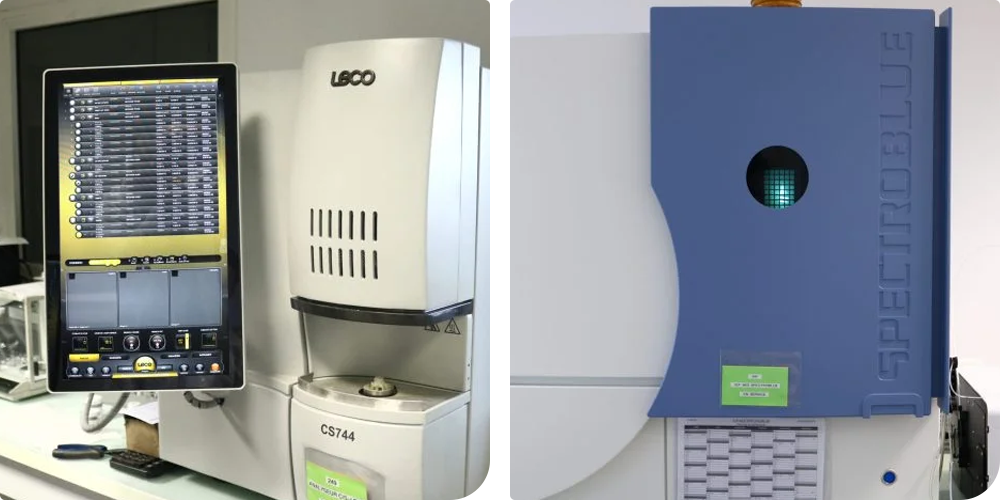

Analysis by elemental analyzer

The purpose of chemical analysis by C/S elemental analyzer is to specifically determine the carbon and sulfur content of the sample.

Analysis by ICP-AES

Analysis by Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES) is used to identify and quantify the chemical elements present in the sample.

These chemical analysis of the piston have shown that the contents obtained are consistent with those of non-alloy structural steel.

Fractographic analysis of the piston

Observation with a binocular magnifying glass

The binocular magnifying glass technique allows macroscopic observations to be made. Observations made with a binocular magnifying glass have yielded the following information:

- The fracture initiation zone follows part of the circumference of the part and is a few millimeters thick.

- Most of the fracture surface has a shiny, grainy appearance with propagation lines and relief features. Dark areas are present and may correspond to contamination or corrosion that appeared after the part broke. A few areas of matting (areas deformed by impact after the break) are also present in small numbers.

- The end of the tear zone was observed. It follows the perimeter of the part over a small portion.

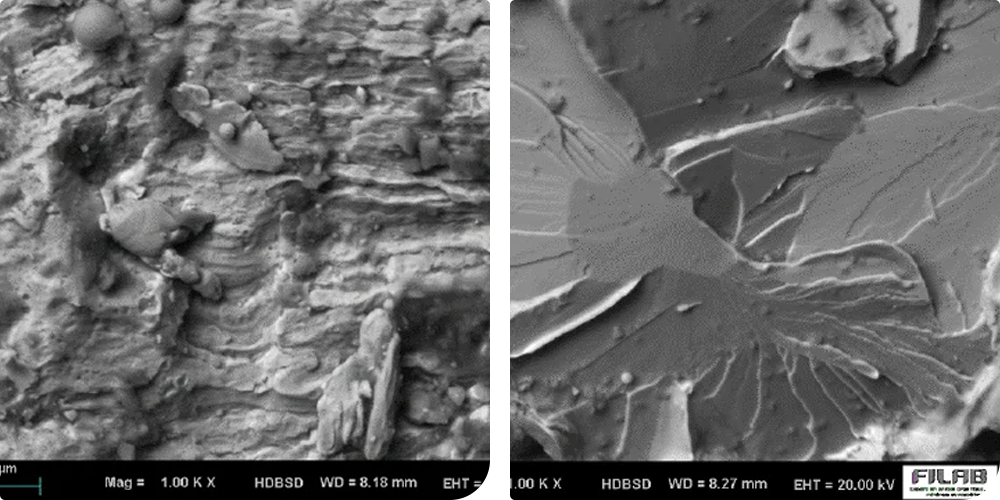

Detailed observations using SEM-EDX

- Micro-striations were identified in the fracture initiation zone. These may have been caused by fatigue in the part. This part of the fracture surface is rich in carbon (C), but this concentration is probably due to organic contamination on the surface

- The majority of the fracture surface corresponds to a transgranular brittle fracture with the presence of cleavage rivers, indicating a sudden fracture.

- The end of the tear zone contains dimples consistent with a ductile fracture. As in the fracture initiation zone, there is a significant amount of organic contamination.

The results obtained...

The chemical analysis carried out in this study made it possible to determine the nature of the piston, which turned out to be non-alloy structural steel.

Furthermore, fractographic analysis identified the fracture initiation zone on part of the circumference of the component. It features micro-streaks, which may have been caused by fatigue (cycles of mechanical loading and unloading under bending).

Most of the fracture surface corresponds to a transgranular brittle fracture with the presence of cleavage rivers, indicating a sudden fracture.

Conclusion of the study

Ultimately, thanks to FILAB's highly specialized intervention, our beloved faulty piston revealed all its secrets.

Like a brilliantly conducted police investigation in the world of steel, the analysis revealed that even the most robust components are not immune to a little fatigue.