Ferroalloy analysis laboratory

Your needs: carrying out laboratory analysis of ferroalloys

What is a ferroalloy?

A ferroalloy is a metal alloy composed primarily of iron and one or more chemical elements (such as chromium, manganese, silicon, vanadium, or molybdenum). These elements are added to iron to improve certain properties of steels or alloys, such as:

mechanical resistance

resistance to corrosion or heat

ease of machining

Ferroalloys are used as additives in the manufacturing processes of steels and specialty alloys, to precisely adjust the chemical composition of materials.

They are found in many industrial sectors: steelmaking, foundries, aerospace, automotive, nuclear, etc.

What ferroalloys can FILAB analyse?

Ferrochrome analysis

Ferrosilicon analysis

Ferromolybdenum analysis

Ferromanganese analysis

Ferrovanadium analysis

Ferrobor analysis

Ferroalloy analysis: an essential control for your metallurgical processes

Guarantee the conformity and performance of your ferrous alloys

Why use a ferroalloy analysis laboratory?

A ferroalloy analysis laboratory is often commissioned by the metallurgical industry to address issues related to the quality, performance, and compliance of metal materials and products.

Ferroalloy analysis verifies the chemical composition of alloys, ensuring that the materials used meet the standards required for specific applications, thus avoiding the risk of failure. Furthermore, these analysis help identify and understand the causes of failures, such as corrosion, fatigue, or fracture, allowing for improved manufacturing processes and material selection.

Ferroalloy services

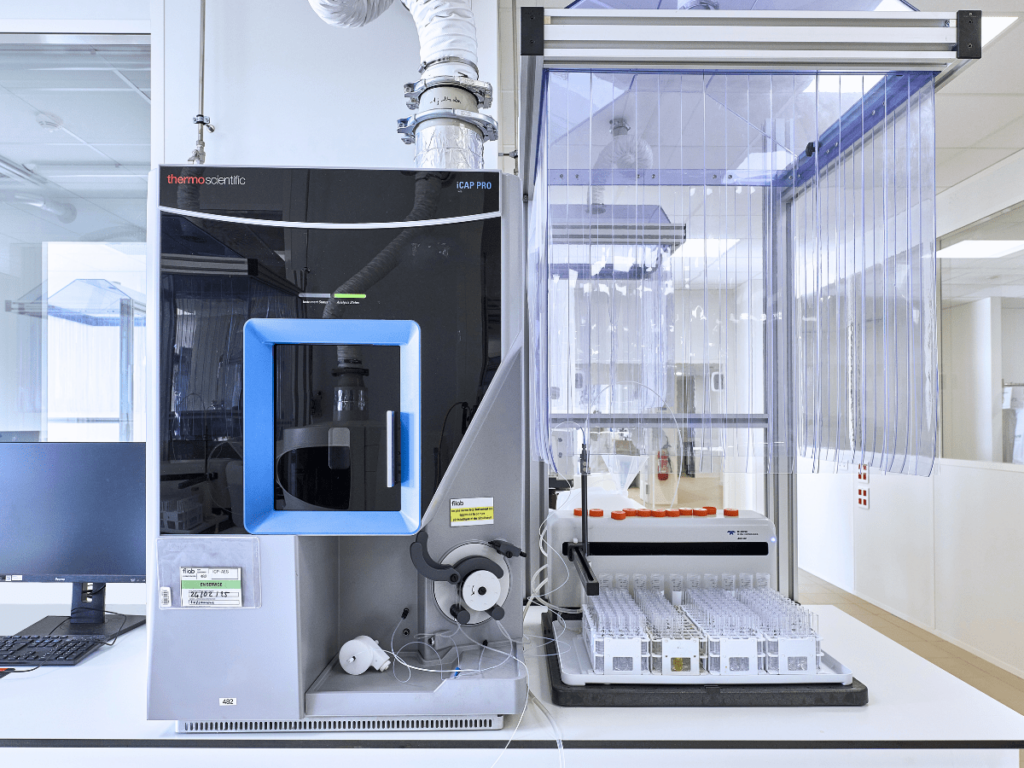

FILAB, laboratory of expertise in metallurgical analysis

For over 30 years, the FILAB laboratory has been offering several thousand clients high added-value metallurgical analysis services, and for certain analysis services, under COFRAC ISO 17025, Pr 6000 and Pr 7210 accreditation from Safran or linked to our customer approvals.

Our chemical analysIs on ferroalloys

FAQ

We analyse :

- Solid ferroalloys

- Metal powders

- Slag or smelting residues

Ferroalloy analysis is used to :

- Accurately check their chemical composition

- Check compliance with standard specifications (ISO, ASTM, etc.)

- Identify impurities or contaminants

- Optimise formulations in metallurgical production processes

A standard ferroalloy has a composition defined by industry standards. A bespoke ferroalloy, on the other hand, is developed to meet specific performance or process requirements and often requires more detailed characterisation.

Yes, using salt spray corrosion testing techniques, we can assess the thermal resistance, oxidability and ageing of ferroalloys under real or simulated conditions.

Yes, X-ray diffraction (XRD) can be used to determine the crystalline phases and characterise the structure of the material (e.g. presence of carbides, ferrite, austenite, etc.).

Exactly. Our analysis can detect metallic impurities (lead, arsenic, mercury, etc.), non-metals (sulphur, phosphorus, etc.) or undesirable inclusions that could alter the final quality.

Yes, beyond the raw analysis, our experts can interpret the results, relate them to your processes or industrial issues, and suggest areas for improvement or formulation adjustments.