Are you looking to cooperate with a specialized laboratory to perform an expertise of your metallic materials ?

Qu'est-ce qu'un matériau métallique ?

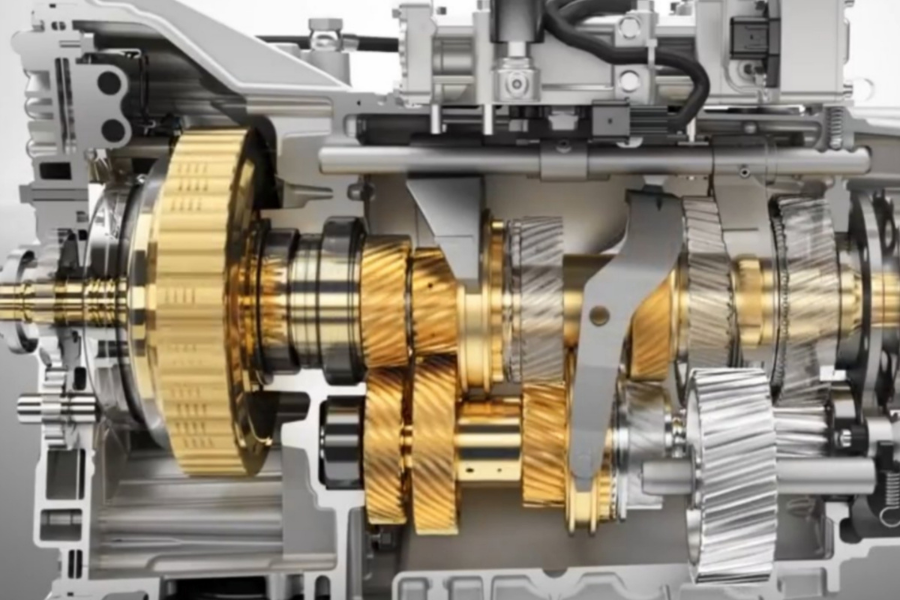

A metallic material is mainly composed of metals. Metals are characterised by their ability to conduct heat and electricity, and the ability to deform under the action of external forces without breaking (ductility and malleability). These properties make metallic materials useful in a wide variety of industrial and metallurgical applications.

Metallic materials can be pure, such as iron, copper, gold and silver, or alloyed, combining two or more metals to improve some of their properties, such as corrosion resistance, hardness or ability to withstand high temperatures.

Steels and aluminium alloys are metallic materials commonly used in the construction, automotive and aerospace industries. The FILAB laboratory has developed material expertise and offers steel analysis.

What is the characterization of a metallic material?

The characterization of a metallic material involves examining and determining its various properties and structure to understand how it behaves and can be used effectively in your industry.

The FILAB laboratory is able to carry out various analysis of metallic materials:

- identify the chemical composition of metal alloys,

- study the internal structure of the metal using metallography,

- measure mechanical properties such as the strength and flexibility of the material.

When characterising metals, other properties are also examined, such as reaction to heat, electrical and magnetic behaviour, and corrosion resistance. These analysis help to select the best metallic material for a specific application, and to improve existing materials, while guaranteeing material quality.

Why carry out a metal appraisal?

The diversity of alloys and surface treatments means that metallic materials are complex to analyse, and require regular inspection to ensure compliance.

Metallic materials are exposed to various stresses throughout their life cycle, such as mechanical loads, temperature variations and wear. These stresses can cause problems such as metal part failure, cracking, corrosion or accelerated ageing of the material.

To deal with production challenges or failure problems, it is essential to rely on a reliable and responsive laboratory specialising in the analysis of metallic materials. Laboratory metallurgical analysis can identify and solve problems related to metallurgical failure, quality and manufacturing defects.

FILAB can help you assess your metal materials

The FILAB laboratory's expertise in metals

Laboratory expertise in metals is based on a combination of advanced technical resources and metallurgical expertise, enabling FILAB, an expert materials laboratory, to carry out comprehensive characterization of metallic materials.

This expertise is based on the use of state-of-the-art analytical equipment dedicated to metallographic analysis, in particular spectrometry for the chemical composition of alloys, X-ray diffraction for the crystalline structure, and electron microscopy for details of the surfaces and fracture surfaces of metal parts.

Mechanical tests, such as tensile, hardness and impact tests, are used to assess the response of metals to different stresses, while thermal analysis help to understand the behaviour of materials at different temperatures. Finally, specific techniques such as corrosion analysis and fatigue testing are used to quantify the durability and longevity of materials under real-life conditions.

The success of these analysis requires not only state-of-the-art equipment, but also in-depth expertise. The FILAB laboratory's certifications and accreditations demonstrate a real analytical strength based on precision and rigour.

Compliance and standards for metallic materials

Standards cover various aspects of metallic materials, from their chemical composition to their specific applications in an industry.

NF 10088 - Standard for stainless steels

Standard 573-3 - Chemical composition of aluminium and aluminium-copper alloys

NF-A36-711 - Steels in the food industry

ISO 17025 - Material characterization tests

ISO 945-1 - Standard for cast iron graphites

Research & development for metals

Using a laboratory for metals research and development (R&D) offers significant advantages for product innovation and improvement.

FILAB's metallurgical expertise enables the laboratory to support you in the development of new materials and alloys with specific properties, such as greater corrosion resistance, improved ductility or greater fatigue resistance.

Being supported by a laboratory with expertise in the characterisation of metallic materials also helps to optimise manufacturing processes and guarantee compliance with industrial standards.

Our FAQ

To have the composition of a metal analysed, you need to contact a laboratory specialising in metallurgy or materials analysis.

The process begins with the selection of representative samples of the material to be analysed, which are then subjected to specific tests. These tests can include techniques such as coupled ICP spectrometry and X-ray fluorescence, which are capable of accurately determining the chemical composition of metals and alloys. At FILAB, we offer analysis of the chemical composition of metal alloys.

It is important to provide the laboratory with detailed information on the context of the analysis, the intended applications of the material, and any particular specifications to be met. The laboratory will carry out the analysis and be able to identify any impurities, as well as assessing compliance with applicable standards. This process helps to ensure that the metallic material meets the quality and performance criteria required for its use.

For further information

The different metallic materials and their industrial applications

Metallic materials include steel, aluminium, bronze, copper, stainless steel, nickel, titanium, tin, etc. The FILAB laboratory offers analysis on all these materials used in the automotive, medical and packaging industries.

Metallic material | Features | Industrial applications |

Steel | High tensile strength, ductility, adaptable via alloys and treatments | Construction, automotive and shipbuilding industries |

Aluminium | Lightweight, corrosion-resistant, excellent conductivity | Packaging, transport, construction |

Copper | Excellent electrical and thermal conductivity, malleable | Electrical wiring and electronics industry |

Titanium | Very strong and light, expensive, corrosion-resistant | Aeronautical industry, medical devices |

Stainless steel | Corrosion and heat resistant, aesthetically pleasing | Medical devices |

Bronze | Strong, corrosion and fatigue resistant | Art, bearings, gears, maritime |

Nickel | Corrosion and heat resistant, magnetic | Batteries, coins, coatings, turbines |

Tin | Low hardness, highly malleable, corrosion-resistant | Welding, coatings for food preservation, alloys |

Example of analysis on metallic materials

In the aerospace industry, laboratory expertise can reveal manufacturing defects that could compromise the strength of a metal part.

In the energy sector, testing the corrosion resistance of metals used in marine environments helps to prevent structural failure.

In the field of medicine and medical devices (implants), expertise also helps to ensure that the materials used are biocompatible and fatigue-resistant.

In short, laboratory expertise in metallic materials is fundamental to optimising manufacturing processes, improving product reliability and meeting the stringent requirements of various industries.