Would you like to carry out a fracture surface analysis on a metal part?

FILAB, a fracture surface analysis laboratory, specialises in the study of fracture surfaces to determine the mechanisms responsible for material failure. Using state-of-the-art equipment, such as scanning electron microscopy (SEM) coupled with chemical analysis using EDX spectroscopy, we help industries to identify the causes of fracture in their raw materials or finished products..

What is a fracture surface?

A fracture surface refers to the surface of a material that has fractured. It can provide valuable information about the reasons for the fracture and the characteristics of the metallic material.

Metallic materials, used in a wide variety of products, are susceptible to fracture over time as a result of wear. Observation of metallographic sections and precise analysis of fracture surfaces (fractography) enable the causes of fracture to be identified.

The fracture surface is the appearance of the surface created by the fracture of a part. Each fracture has a specific fracture surface, making it possible to identify the cause and origin of the fracture: fractography is the art of analysing the fracture surface of broken parts.

Types of fracture surfaces

This type of fracture involves significant plastic deformation before fracture. Example: Metal stretched before breaking shows a ductile fracture surface with deformation cavities.

Fracture occurs without significant deformation, leaving a clean fracture. Example: A ceramic part that breaks suddenly.

This occurs as a result of repeated load cycles, forming progressive cracks. Example: A turbine blade subjected to vibrations.

Caused by the chemical degradation of a material combined with mechanical stress. Example: A corroded metal pipe in a marine environment that cracks.

The FILAB laboratory can help you with fractographic analysis of metal parts

For over 30 years, the FILAB laboratory has had the experience and specific analytical equipment to support companies in the analysis and study of fracture surfaces on metal parts, through tailor-made support.

From analysis to R&D support, the FILAB laboratory offers multi-sector expertise to deal with your various fractographic problems:

Our technical resources for analysing a fracture surface

This fractographic expertise will make it possible to locate the onset of the fracture, identify its extension and highlight any material defects or external pollution that may have caused it. The FILAB laboratory can help you understand and solve your fracture problems.

For this type of service, the FILAB laboratory uses cutting-edge analysis techniques such as :

Our expertise in fracture surface analysis includes the identification of microscopic defects, such as inclusions or microcracks, which are often the cause of material failure.

Our failure analysis services

In addition to fracture surface analysis using fractography, the FILAB laboratory offers other analysis services to characterise metallic materials and identify metallurgical failures :

Analyse the fracture surface

Study the effectiveness of a surface treatment system

Validate the conformity of a surface

Characterise the causes of wear on a material

Assess the risk of wear on a material in a given environment

Our metal analysis services

Analysis of fracture surfaces

Fracture surface analysis, also known as fractographic analysis, is a laboratory analysis used by industry to determine the causes of fractures in metal parts. This method is based on visual examination of fracture surfaces to determine their appearance characteristics, followed by microscopic analysis. Internal defects, such as cracks, inclusions or areas of weakness, can be detected using this technique.

Fracture facies analysis can reveal:

The type of fracture: ductile fracture, brittle fracture or mixed fracture.

The critical zones: initiation, propagation and termination of the fracture.

The mechanical or chemical phenomena at the origin of the fracture,

Causes of material failure

The fracture surface is caused by multiple conditions such as :

Why call in a laboratory in the case of metal fractures?

The analysis of materials following a metallic fracture provides an understanding of the factors contributing to the failure of the metallic structure, enabling the development of preventive measures to avoid future fractures and improve the quality of metallic materials.

The FILAB laboratory offers high quality services to help determine the reasons for metallic failure (overstress, corrosion, fatigue or a combination of factors), and to prevent its recurrence.

Fracture analysis is part of our expertise in metallic materials and metallurgical failures.

Our expertise in analysing fracture surfaces

The FILAB laboratory analyses fracture surfaces for a wide range of materials:

- Metals: steel fracture surfaces, aluminium fracture surfaces, ductile or heat-treated metals.

- Glass: identification of fracture surfaces in toughened or bent glass.

- Polymers and composites: observation of SEM images of polymer fracture surfaces and glass fibre or composite charpy fracture surfaces.

Tailor-made support

Whether you are faced with a sudden rupture, a progressive crack or material fatigue problems, FILAB can help you with your projects. Our analyses guarantee the quality and safety of your products, while complying with the strictest industrial standards. Do you have a question or would you like to carry out an analysis? Contact our experts for a personalised quote.

Examples of industrial applications

Our expertise enables us to respond to the problems faced by the following industries:

- Fractures in metal alloys: determination of the stresses that led to fractures.

- Fracture studies in composites: analysis of charpy composite fracture surfaces to optimise their durability.

- Observation of fracture surfaces in polymer materials: detection of fatigue-related brittleness.

Fracture facies and metallurgical failure analysis

In a metallurgical failure analysis, examination of the facies helps to determine whether the failure is due to phenomena such as fatigue, corrosion or mechanical overload. By combining techniques such as scanning electron microscopy (SEM) and fractography, our experts identify the mechanisms behind the failure, helping to prevent future failures in industrial processes.

FAQ

Identifying a fracture surface on a metal part can be a real challenge for industry professionals. Yet it is essential to detect signs of fatigue, corrosion or cracks that can cause costly failures. By correctly identifying the fracture surface, manufacturers can determine the nature of the problem and take the necessary measures to avoid negative consequences for the quality and safety of metal parts.

To make the use of metal parts more reliable, manufacturers can carry out mechanical tests and chemical analyses prior to breakage. The most common analyses include

- tensile tests, bending tests, compression tests, fatigue tests

- corrosion analysis, analysis of mechanical alloys

A fracture surface analysis involves studying the characteristics of the surface to deduce the mechanical properties that led to the fracture. To carry out such an analysis, we generally proceed in three stages. Firstly, the sample in question must be prepared so that it has a fracture surface. Next, this surface is observed using an optical or electron microscope to identify the different fracture zones. Finally, we study the morphological and mechanical characteristics of these zones, such as the presence of microcracks or deformations, to understand the fracture mechanisms involved.

Analysis of fracture surfaces is essential for :

- Identify the causes of failure and prevent their recurrence.

- Understand the interactions between conditions of use (temperature, pressure, mechanical load) and the behaviour of materials.

- Improve industrial processes by optimising the selection and treatment of materials.

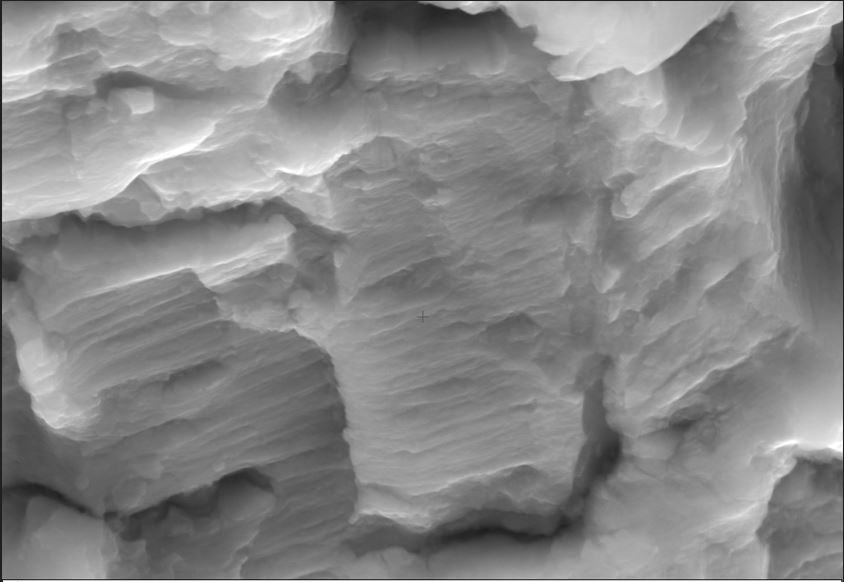

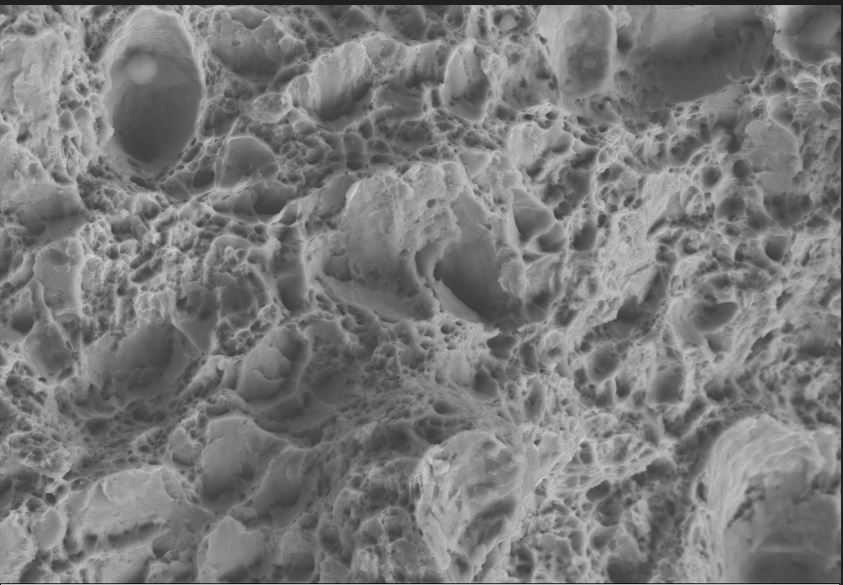

- Ductile fracture: This type of fracture is characterised by significant plastic deformation prior to fracture. When a metal such as mild steel fractures ductilely, microscopic cavities (porosities) appear, which coalesce to form a fracture. This type of fracture is often granular, with tear-forms.

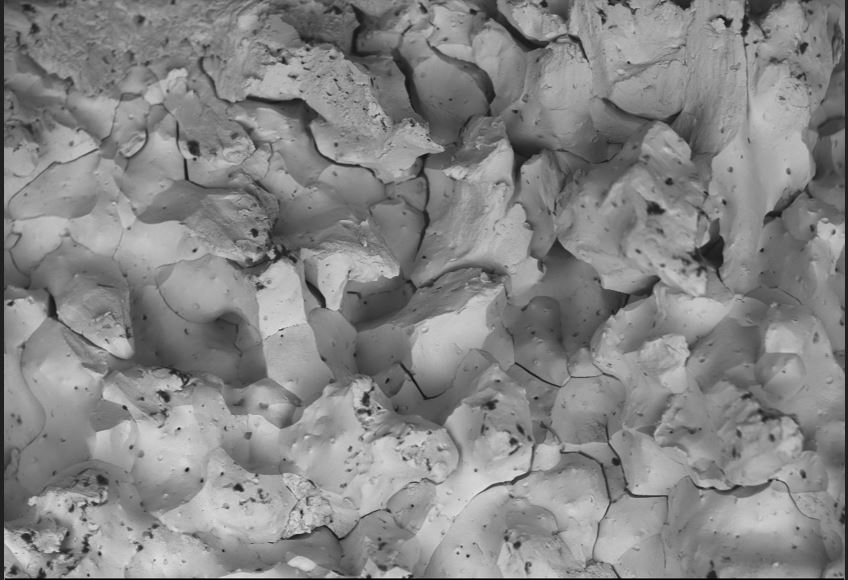

- Brittle fracture facies: In this case, fracture occurs without plastic deformation. This is typical of metals subjected to low temperatures or hard materials such as cast iron. The fracture surface is usually shiny and smooth with characteristic patterns, such as crystalline facets.

- Fatigue fracture facies: This facies occurs after repeated stress cycles, even if the applied stresses are below the metal's elastic limit. It is characterised by visible fatigue striations on the fracture surface, representing the stages of crack propagation. This type of fracture is common in metals such as aluminium alloys used in aviation.

- Corrosion fractures: This type of fracture, often called stress corrosion, is linked to the interaction between mechanical stresses and a corrosive environment. It is characterised by cracks that are often fine and branched, with signs of chemical degradation around the fracture zone. Stainless steels in a chlorinated environment are a good example.

A screw fracture pattern shows clues as to how a screw broke. This can include fatigue fractures, sudden failure under excessive stress or failure due to corrosion.

In aluminium, fracture surfaces can vary from ductile (significant deformation before fracture) to brittle (clean, rapid fracture, typical at low temperature or in fatigue).

The torsional fracture surface generally shows a helical fracture with striations or spiral cracks due to excessive torsional movement.

A brittle fracture occurs with little or no plastic deformation, leaving a smooth, shiny fracture surface, whereas a ductile fracture shows clear signs of deformation before fracture, with a granular fracture surface.

This facies forms progressively under repeated loading cycles. It is often characterised by fatigue striations that represent the stages of crack advancement before final fracture.