Your needs: characterize the extreme surface chemical composition of a sample using TOF-SIMS analysis

FILAB offers advanced ToF-SIMS (Time-of-Flight Secondary Ion Mass Spectrometry) analysis and testing to help manufacturers, engineers, and R&D teams characterize the extreme surface of their materials with unrivaled chemical precision.

By bombarding the material with a pulsed primary ion beam, ToF-SIMS enables the detection and imaging of molecular and elemental fragments on the outermost nanolayers (typically <2 nm). Whether you are dealing with contamination, adhesion failure, residue identification, or interface analysis, our ToF-SIMS laboratory provides the high-resolution insight needed to solve complex problems.

What is ToF-SIMS and why use it?

Identifying unknown contaminants or residues (organic/inorganic)

Characterizing layered structures and thin films

Mapping lateral and vertical distribution of compounds in 2D and 3D

Studying interfaces in adhesives, paints, coatings, or semiconductors

Thanks to its broad dynamic mass range and ultra-high sensitivity, ToF-SIMS outperforms traditional surface methods when specificity and spatial resolution are critical.

TOF SIMS analysis

TOF SIMS analysis is a cutting-edge technique, offering sensitivity and high molecular resolution for extreme surface analysis and the study of the chemical compositions of materials.

TOF-SIMS analysis provides qualitative and semi-quantitative information on the elements and molecules present.

Furthermore, it is a high-resolution imaging technique that maps the distribution of elements and molecules on the surface of a sample with high spatial resolution. This capability allows the FILAB laboratory to understand surface heterogeneities and material interfaces.

In short, it provides information on the chemical composition, spatial distribution of elements, and chemical bonds of the sample.

Why perform a TOF SIMS analysis in the laboratory?

TOF SIMS analysis is particularly valued for its ability to provide detailed information on the chemical composition of materials, both at the surface and at depth (down to 1 nm).

It not only allows for surface examination to identify the elements and molecules present, but also allows for depth profiles to be created by progressively removing layers, revealing compositional variations at different levels. This technique is thus distinguished by its ability to identify the molecular structure of compounds.

Essential for surface studies, this dual analysis capacity, spatial and molecular, makes TOF SIMS analysis essential for surface studies, the study of interactions between materials, understanding the presence of corrosion, the analysis of coatings and many other applications.

The surface sensitivity of the sims analysis

ToF-SIMS is therefore a very highly sensitive surface analysis technique that achieves detection limits for elements or molecules in the ppm range.

The high sensitivity of TOF-SIMS makes it an excellent initial tool for identifying the types of species present in a sample. Once SIMS analysis is complete, other methods, such as XPS, can be used to obtain more detailed information. Moreover, SIMS analysis can detect species at much lower levels than traditional systems.

Materials and Surfaces concerned

This technique can be applied to a wide variety of materials, including polymers, metallic materials, ceramics, and composite materials, films, glass and fiberglass, dental implants, and more, without requiring complex sample preparation.

All conductive and insulating materials that are stable under ultra-high vacuum can be analyzed by ToF-SIMS: metals, alloys, semiconductors, polymers, varnishes, paints, adhesives, additives, surfactants, ceramics, glass, wood, paper, textiles, ultra-high vacuum, thin films, and more.

Our solutions : offer TOF-SIMS analysis techniques specific to your requirements and deliver fast, reliable results

ToF-SIMS Analysis & Testing Laboratory – Ultra-Sensitive Surface Characterization

FILAB offers advanced ToF-SIMS (Time-of-Flight Secondary Ion Mass Spectrometry) analysis and testing to help manufacturers, engineers, and R&D teams characterize the extreme surface of their materials with unrivaled chemical precision.

By bombarding the material with a pulsed primary ion beam, ToF-SIMS enables the detection and imaging of molecular and elemental fragments on the outermost nanolayers (typically <2 nm). Whether you are dealing with contamination, adhesion failure, residue identification, or interface analysis, our ToF-SIMS laboratory provides the high-resolution insight needed to solve complex problems.

Our ToF-SIMS capabilities at FILAB

Our laboratory is equipped with a state-of-the-art ToF-SIMS instrument operating under ultra-high vacuum and capable of:

- High-resolution 2D imaging (<100 nm lateral resolution)

- 3D depth profiling using dual-beam sputtering

- Full mass spectrum acquisition (1–2000+ amu)

- Elemental and molecular ion detection (positive and negative modes)

- Quantification and distribution analysis of elements, fragments, and molecules

We combine ToF-SIMS with complementary surface techniques such as XPS (X-ray Photoelectron Spectroscopy), FTIR, SEM-EDX, or AFM, depending on your project.

Our TOF SIMS analysis services

In demanding sectors (microelectronics, biomaterials, coatings, etc.), detecting contamination or characterizing thin films at the nanoscale is essential. Contamination, adhesion defects, and processing non-conformities: these issues can compromise the quality and reliability of your products.

SIMS analysis, and particularly the TOF-SIMS technique, enables ultra-sensitive chemical identification of surfaces and interfaces. It addresses the challenges of quality control, failure assessment, and the development of innovative materials. FILAB supports you with cutting-edge equipment and expertise in extreme surface areas for your SIMS analysis needs.

Surface chemical characterization for R&D and process optimization

Comparative study between different treatments or formulations

Determination of the crosslinking rate of a plasma polymer (evaluation of surface functionalization)

Feasibility study for the implementation of a process or coating

Differentiation of silicon (Si) chemistry according to oxidation states or treatments undergone

Contamination analysis and surface diagnosis

Identification of pollution or surface deposit of a material (elementary and molecular diagnosis)

Delamination of a paint (fracture interface analysis)

Paint discoloration (search for contaminants or chemical alterations)

Particle analysis (localized chemical characterization of an inclusion or deposit)

Functional verification of surfaces

Detection of all elements down to ppm (traces of contaminants or additives)

Verification of the surface function of a product in relation to its adhesion or mechanical grip performance

Qualitative analysis to ensure the presence or absence of certain functional chemical compounds

Multi-layer material studies and depth profiling

Multi-layer analysis (composition, thickness, sequence of thin layers)

Profiling an organic sample with an argon aggregate beam, allowing the maintenance of molecular information in depth (up to 3 to 10 µm max)

High-resolution elemental and molecular analysis

Atomic and molecular identification over a wide mass range (from 0 to 10,000 amu)

Isotopic analysis to differentiate isotopes of the same element or to trace specific markings

These extreme surface analysis therefore allow you to ensure the conformity of your products and to respond to your industrial problems of failures and identification of pollution.

And also

Applications of ToF-SIMS analysis

At FILAB, ToF-SIMS testing is routinely used in industrial contexts where surface performance is critical. Our lab supports clients across:

- Medical devices : analysis of coatings, lubricants, or pharmaceutical residues

- Microelectronics : contamination tracking, wafer analysis, metal-organic interfaces

- Packaging & polymers : layer identification, print residue, adhesive bonding studies

- Aerospace & automtotive : failure analysis of treated metal surfaces, paints, or seals

Whether you're qualifying a supplier process, solving a failure, or launching a new formulation, ToF-SIMS gives you the surface-level answers you need.

FAQ

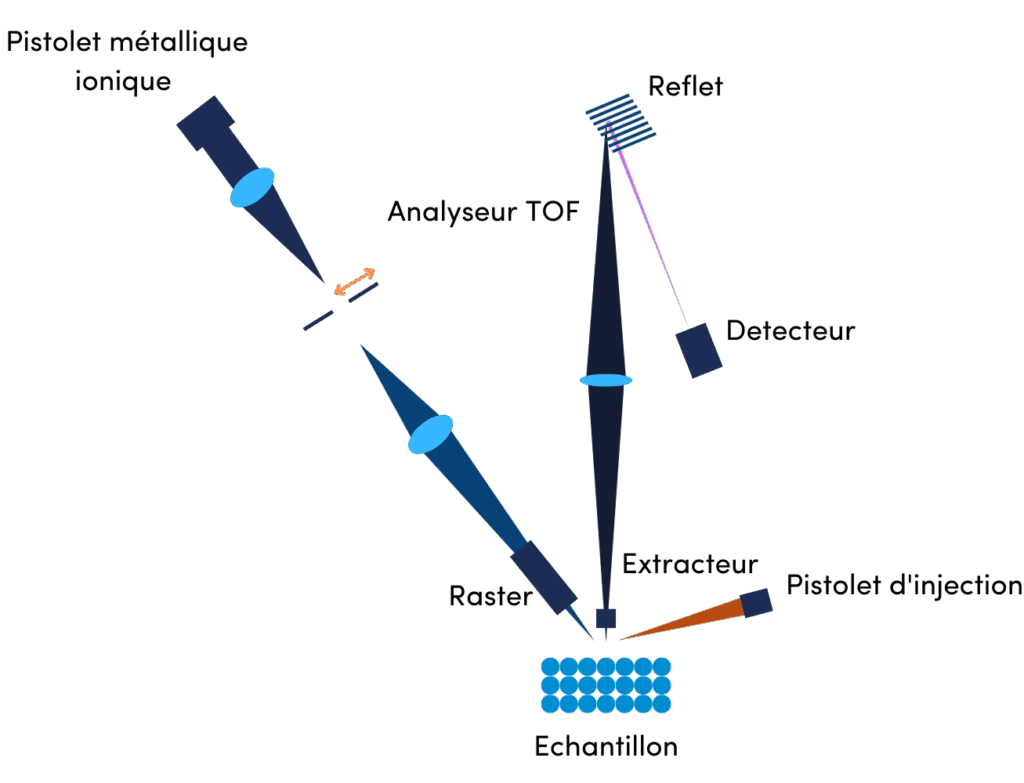

Extreme surface analysis by TOF-SIMS involves first preparing the sample, then introducing it into the spectrometer's vacuum chamber. A beam of primary ions bombards the surface, releasing secondary ions which are then identified by their time-of-flight, enabling the chemical composition of the surface to be determined.

The principle consists in bombarding the surface to be analyzed with a pulsed source of primary ions (Ga+, Bin+, Au+, C60+, ...) to produce secondary ions from the first monoatomic layers of the sample. These secondary ions, whether positive or negative, are then focused and accelerated in a time-of-flight analyzer, where their travel time is a function of their mass. Coupled with a scanning device for the primary ion beam, this provides a map of the various chemical elements and molecular species on the sample surface.

TOF-SIMS can detect elements at extremely low concentrations, down to levels of a few parts per million (ppm), depending on the sample matrix and experimental conditions.

SIMS analysis is a laboratory technique for determining the composition of a material by bombarding its surface with ions. This bombardment releases particles from the surface of the material, which are then analyzed to identify the chemical elements and their quantities. This method is highly accurate, but destructive: it can detect very small quantities and can damage the sample.

In static SIMS analysis, a pulsed primary beam targets only the first monolayer of the sample.

Unlike dynamic SIMS analysis, this approach preserves the molecular integrity of the surface. Molecules are simply desorbed or fragmented into several pieces. Secondary ions, consisting of fragments of the initial molecules, are then detected by a time-of-flight spectrometer. Molecular ions weighing up to 10,000 amu can be identified, providing detailed information on the molecular structure of organic compounds.

TOF-SIMS analysis can identify traces of contamination, characterize thin layers, or study the chemical homogeneity of critical surfaces. It is particularly useful in sectors where surface quality directly influences product performance: microelectronics, biomaterials, technical coatings, etc.

Contamination, even at trace levels, can impair the adhesion of a coating, cause premature corrosion, disrupt a chemical reaction or generate manufacturing defects. TOF-SIMS analysis allows these contaminants to be precisely located and identified.

Yes, TOF-SIMS is a key tool in non-conformity investigations. It allows for the analysis of very localized areas, such as cracks, bubbles, delaminations, or defective interfaces, to understand the chemical cause.

Perfectly. TOF-SIMS analysis enables depth profiling with nanometer resolution, ideal for characterizing the thickness, composition and order of layers in multilayer systems.

TOF-SIMS is one of the most sensitive surface analysis techniques: it can detect concentrations at the ppm (parts per million) level, or even lower, in the first few nanometers of a material.

TOF-SIMS can analyze extremely small areas, down to a few square microns, making it an ideal method for localized studies or on precise defects.

Yes. Unlike other techniques, static TOF-SIMS preserves organic molecular fragments, making it possible to identify polymers, lubricants, additives, biological residues, or other organic compounds.