Laboratory Analysis and Expertise of Cast Iron - Metallurgical Expertise

Our laboratory is an expert in the metallurgy and analysis of alloys, particularly cast iron, and offers its expertise in analysing the chemical composition and controlling the grades of metal alloys.

Your needs: to carry out an analysis of the cast iron alloy

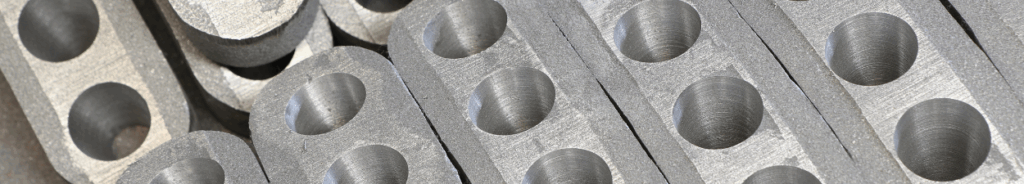

Cast iron is an alloy of iron and carbon containing more than 2% carbon. It is produced by smelting iron ore in a blast furnace, where it is separated from the slag and cast in the form of ingots or directly transformed.

Other elements, such as silicon, manganese or sulphur, may be added to improve its mechanical properties, hardness and fluidity.

There are several types of cast iron, classified according to their chemical composition and physical and chemical characteristics:

The different types of cast iron and alloys

Each type of cast iron is chosen according to the specific requirements of strength and durability.

Analysis of cast iron composition: essential quality control

Analysis of the chemical composition of cast iron enables the presence and concentration of essential alloying elements such as iron, carbon and phosphorus to be verified, ensuring the conformity of materials for safety- and performance-critical applications.

The FILAB laboratory, specialist in metallurgical and cast iron analysis

The FILAB laboratory offers several hundred customers metallurgical analysis services on cast irons, some of which are COFRAC ISO 17025 accredited.

The FILAB laboratory puts its experience and specific skills at your disposal to control the quality of your cast irons.

Our cast iron analysis methods

We use advanced analytical techniques, such as spectrometry and ICP analysis, to accurately detect the chemical composition of cast iron and its alloys. These methods make it possible to measure elemental content and ensure the quality of materials.

Our analysis of metals and alloys

Iron: steel, steel 316l, stainless steel

Cobalt : Cobalt Stellite Grade 6, Cobalt Stellite Grade 21

Composition analysis enables quality control and ensures the conformity of cast iron for demanding industrial applications.

Analysis of the chemical composition and grade control of cast iron alloys

To see further: our expertise in cast iron alloys

In addition to routine metallurgical analyses, the FILAB laboratory can provide you with expert metallurgical analyses and failure studies on your cast iron samples:

Metallographic examination of cast iron

Weld analysis on cast iron

Study of fracture surfaces on cast iron

Study of ageing (corrosion, surface alteration, etc.) on cast iron

Thickness measurement of cast iron part coatings

Study of corrosion resistance on cast iron

Analysis and characterization of cast iron surfaces (roughness, defects, etc.)

Analysis Alloy composition

Study of microstructures on cast iron material

Analysis of cast iron alloys according to ISO and NF standards

Our laboratory complies with the reference standards for the analysis of cast iron alloys, guaranteeing results that comply with ISO and NF standards.

Applications of cast iron alloy analysis

The analysis of cast iron alloys is commonplace in sectors where cast iron is widely used, such as the automotive, mechanical and energy industries. Whether to check corrosion resistance, durability or material safety.

Why choose our laboratory to analyse cast iron and its alloys?

Our FILAB laboratory offers services dedicated to the analysis of cast iron and its alloys, tailored to the specific needs of each industry. Analysing the composition of cast iron can address a number of industrial issues:

FAQ

Alloy cast iron is often less expensive, easier to mould and better at damping vibrations. It is ideal for complex parts with a high mass or subject to high compressive stresses.

- Brinell / Vickers hardness

- Tensile strength

- Impact strength (Charpy test)

- Fatigue tests (for nodular cast iron)

Yes, some cast irons (alloyed with Mo, Si, Ni...) can withstand high temperatures (> 600°C), particularly in exhaust systems or boilers.

- Surface treatments (paint, zinc plating, phosphating, etc.)

- Choice of alloys (nickel or copper cast iron)

- Enamelled coatings (e.g. cookware)